In today's fast-paced industrial landscape, advanced electrical tools for automation are not just a luxury but a necessity. These tools, ranging from sophisticated sensors to intelligent control systems, are transforming how industries operate, making processes more efficient, safer, and more cost-effective. This article delves into the world of these cutting-edge tools, exploring their applications, benefits, and the future they promise.

Automation in electrical systems refers to the use of technology to control and monitor electrical processes with minimal human intervention. This can range from simple tasks like turning on lights when someone enters a room to complex operations in manufacturing plants where entire production lines are automated. The primary goal is to increase efficiency, reduce errors, and free up human workers for more strategic tasks.

Several tools are pivotal in the automation of electrical systems. These include:

- Industrial Sensors: Devices that detect changes in the environment and send signals to control systems. Examples include temperature sensors, pressure sensors, and proximity sensors.

- Programmable Logic Controllers (PLCs): Digital computers used to control manufacturing processes, such as assembly lines or robotic devices.

- Human-Machine Interfaces (HMIs): User interfaces that allow humans to interact with machines, often through touch screens or other input devices.

- Automation Software: Programs that integrate and manage the various components of an automation system, providing real-time data and analytics.

Industrial sensors are the backbone of automation. They provide the data that automation systems need to make decisions. For instance, a temperature sensor in a chemical plant can trigger cooling systems if the temperature exceeds a certain threshold, preventing overheating and potential disasters. There are various types of sensors, each suited for specific applications:

- Temperature Sensors: Measure heat levels.

- Pressure Sensors: Detect changes in pressure.

- Proximity Sensors: Detect the presence of objects without physical contact.

- Flow Sensors: Measure the flow rate of liquids or gases.

Understanding the different types of sensors and their applications is crucial for designing effective automation systems.

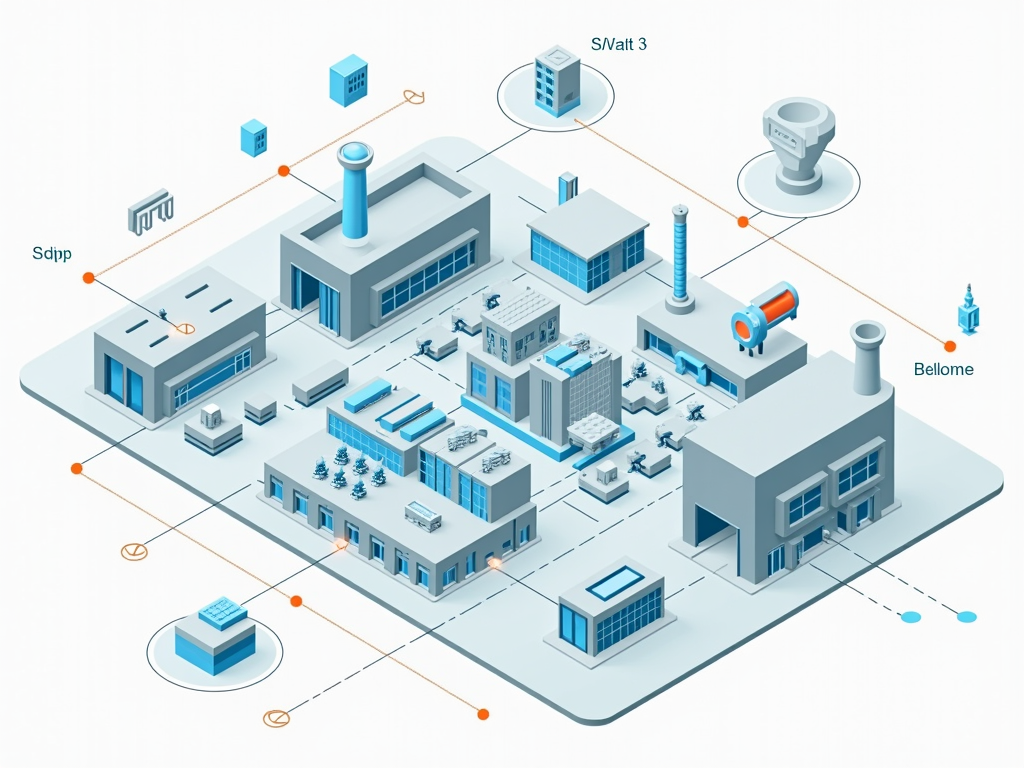

To illustrate the impact of these tools, consider the automotive industry. In modern car manufacturing plants, automation is ubiquitous. Robots equipped with sensors and controlled by PLCs assemble vehicles with precision and speed that human workers cannot match. For example, proximity sensors ensure that parts are correctly aligned before welding, reducing errors and improving quality.

Another example is in the energy sector, where smart grids use sensors and automation software to monitor and manage electricity distribution, reducing waste and improving reliability.

The benefits of implementing these tools are manifold:

- Increased Efficiency: Automated systems can operate 24/7 without fatigue, significantly boosting productivity.

- Improved Safety: By automating dangerous tasks, the risk to human workers is minimized.

- Cost Savings: Although the initial investment can be high, the long-term savings from reduced labor costs and increased efficiency are substantial.

- Enhanced Quality: Automation reduces human error, leading to higher quality products.

For instance, a study by the Massachusetts Institute of Technology found that automation in manufacturing can increase productivity by up to 30% (MIT Study on Automation).

Despite the advantages, there are challenges to consider:

- High Initial Costs: Setting up an automation system can be expensive.

- Training Requirements: Workers need to be trained to operate and maintain these systems.

- Compatibility Issues: Integrating new tools with existing systems can be complex.

It's essential to carefully plan and assess the needs of the organization before embarking on an automation project.

The future of automation in electrical systems is exciting. Emerging technologies like artificial intelligence (AI) and the Internet of Things (IoT) are set to take automation to new heights. AI can enable predictive maintenance, where systems anticipate failures before they occur, while IoT allows for greater connectivity and data sharing between devices.

For example, in a smart factory, machines can communicate with each other to optimize production schedules in real-time, further enhancing efficiency.

In conclusion, advanced electrical tools for automation are revolutionizing industries by making processes more efficient, safer, and cost-effective. From industrial sensors to sophisticated control systems, these tools are indispensable in the modern industrial landscape. As technology continues to evolve, the potential for automation will only grow, promising even greater advancements in the future.

Related advanced-electrical-tools-for-automation:

- The Ultimate Guide to Hand Tools

- Must-Have Wrenches for Every Toolbox

- Upgrading Your Home’s Electrical System

- Screwdriver Safety Tips for Beginners: Essential Guide for Safe Tool Use

- DIY Projects for Beginners: A Guide to Getting Started and Maintaining Your Tools

- How to Use Wrenches Safely: A Comprehensive Guide

- The Science Behind Power Washers: How They Work

- Top Workman Tools: Brands You Need to Know

- Advanced Techniques for Workshop Organization

- The Ultimate Guide to Tool Belts with Built-in Storage

- Essential Gear for New Contractors: Building Your Toolkit for Success

- 10 Must-Have Painting Tools for Faster Projects