Maintaining your tools is crucial for ensuring their longevity and optimal performance. In this article, we'll explore essential tips for tool maintenance, share personal insights, and provide actionable advice to help you keep your tools in top condition.

Understanding Tool Maintenance

What is Tool Maintenance?

Tool maintenance refers to the regular care and upkeep of tools to ensure they function correctly and last longer. This includes cleaning, lubricating, sharpening, and storing tools properly.

Why is it Important?

Proper maintenance prevents tools from deteriorating, reduces the risk of accidents, and saves money by avoiding premature replacements. Well-maintained tools also perform better, making your work more efficient.

Common Misconceptions

Many people believe that tool maintenance is time-consuming or unnecessary for infrequently used tools. However, even occasional use requires proper care to prevent rust and damage.

Essential Tips for Tool Maintenance

Tip 1: Regular Cleaning

Cleaning your tools after each use is fundamental. For hand tools and workman tools for metalworking, remove dirt, grease, and metal shavings with a brush or cloth. For stubborn grime, use a mild solvent or soapy water, then dry thoroughly to prevent rust. Cleaning tools isn't just about aesthetics; it's about functionality. A dirty saw blade can bind in wood, while a grimy wrench might slip, causing injury. Pay attention to hard-to-reach areas and consider the tool's material when choosing cleaning methods.

Tip 2: Proper Storage

Store tools in a dry, cool place to avoid moisture and heat damage. Use toolboxes, pegboards, or wall-mounted racks to keep tools organized and easily accessible. For metal tools, consider silica gel packs to absorb moisture. The way you store your tools can significantly impact their longevity. Hanging tools on a pegboard allows air circulation, reducing moisture buildup. If using a toolbox, ensure it's lined with foam or has individual compartments to prevent tools from banging against each other.

Tip 3: Lubrication and Rust Prevention

Lubricate moving parts of tools like pliers and wrenches with a light machine oil to ensure smooth operation. For rust prevention, apply a thin coat of oil or use rust-inhibiting sprays on metal surfaces.

Tip 4: Sharpening and Calibration

Keep cutting tools sharp for efficient performance. Use sharpening stones or files for blades, and ensure measuring tools like calipers are calibrated regularly for accuracy.

Tip 5: Inspection and Repair

Regularly inspect tools for signs of wear, such as cracks, bends, or loose parts. Address minor issues promptly, like tightening screws or replacing worn grips, to prevent further damage.

Personal Insights and Experiences

In my years of working with tools, I've learned that maintenance is not just about preserving the tools but also about respecting the craft. I recall a time when I neglected to clean my metalworking tools after a project, and within weeks, rust had set in, rendering them nearly unusable. It was a costly lesson that taught me the importance of regular care.

Another experience that stands out is when I invested in a high-quality toolbox with custom slots for each tool. Not only did it make my workspace more organized, but it also made me more mindful of returning tools to their proper place after use, reducing the chances of loss or damage.

Common Mistakes in Tool Maintenance

Many people make mistakes that can shorten the lifespan of their tools. Here are some common errors to avoid:

- Using the Wrong Cleaning Agents

-

Harsh chemicals can damage tool surfaces. Stick to mild soaps or specialized tool cleaners.

-

Improper Drying

-

Leaving tools wet can lead to rust. Always dry tools thoroughly after cleaning.

-

Over-Lubrication

-

Excess oil can attract dirt and grime. Apply lubricants sparingly.

-

Neglecting Safety Gear

-

When maintaining tools, especially sharpening, wear appropriate safety gear like gloves and goggles.

-

Ignoring Manufacturer Instructions

- Each tool may have specific maintenance requirements. Refer to the manufacturer's guidelines.

Advanced Maintenance Techniques

For those looking to take their tool maintenance to the next level, consider these advanced techniques:

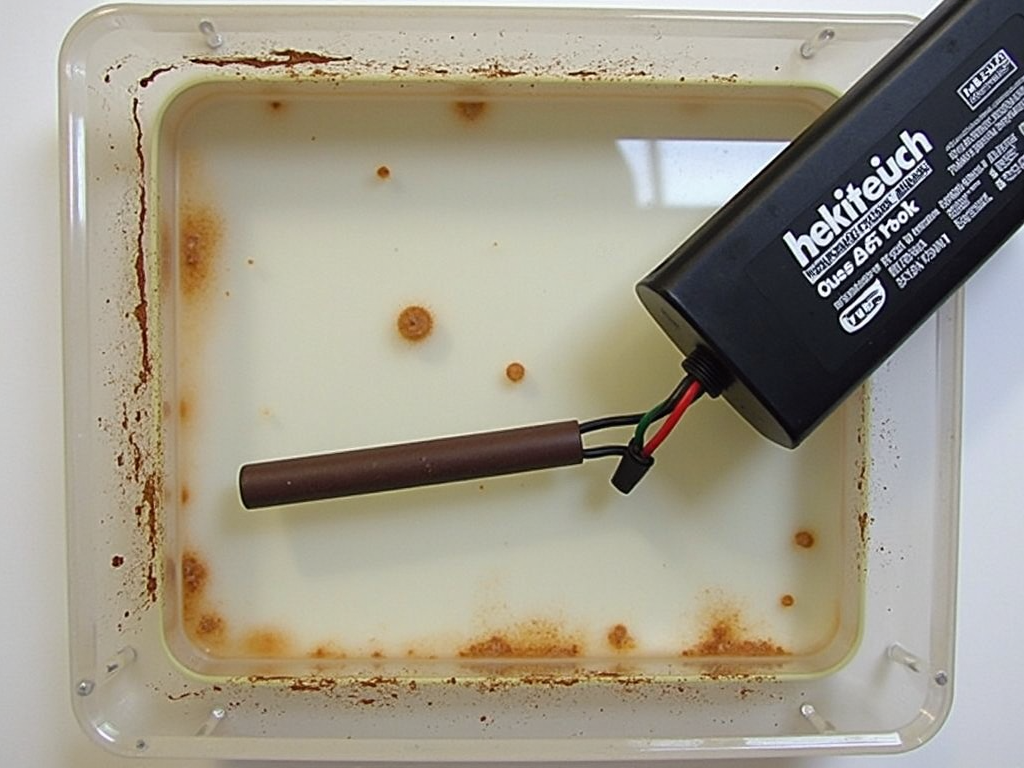

- Electrolysis for Rust Removal

-

A method to remove rust from metal tools using an electrolytic solution and a battery charger.

-

Precision Calibration

-

Use calibration tools to ensure measuring instruments are accurate to the finest degree.

-

Custom Tool Modifications

-

Tailor tools to specific needs, like adding custom grips or modifying handles for better ergonomics.

-

Seasonal Maintenance Routines

- Adjust maintenance practices based on seasons, such as extra rust prevention in humid months.

In conclusion, maintaining your tools is an essential practice that pays off in the long run. By following these tips—regular cleaning, proper storage, lubrication, sharpening, and inspection—you can ensure your tools remain in excellent condition, ready for any task. Remember, a little care goes a long way in extending the life of your tools and enhancing your workmanship.

Related Essential Tips for Tool Maintenance:

- Safety Tips Every Workman Should Know

- The Essential Toolkit: Must-Have Tools for DIY Enthusiasts

- Power Drills 101: Choosing the Right One

- Top 10 Innovative Workman Tools in 2024

- The Ultimate Guide to High-Quality Workman Tools for Professionals

- Ultimate Guide to DIY Tools Maintenance: Screwdriver Edition

- Wrench Care Basics: Keep Them Like New

- Understanding Hammer Dynamics and Ergonomics

- DIY Painting Hacks for Perfect Results

- DIY Maintenance Projects for Beginners: A Step-by-Step Guide

- Popular Brands for Workman Tools: A Comprehensive Guide

- Corded vs. Cordless Power Tools: Which is Best for Your Repair Projects?