The world of workshop equipment is evolving rapidly, driven by technological advancements and changing industry needs. From automation and smart tools to sustainability and safety enhancements, the future of workshop equipment promises to be more efficient, precise, and user-friendly. In this article, we'll explore the key trends shaping the future of workshop equipment and what they mean for professionals and hobbyists alike. Whether you're a seasoned mechanic or a DIY enthusiast, staying informed about these trends can help you make better decisions and stay ahead in your field.

Automation and Robotics

One of the most significant trends in workshop equipment is the increasing use of automation and robotics. Robotic arms, automated guided vehicles (AGVs), and other robotic systems are becoming more common in workshops of all sizes. These technologies can handle repetitive tasks, lift heavy objects, and perform precise operations, reducing the physical strain on workers and improving overall efficiency.

For example, in an automotive workshop, a robotic arm can be programmed to assist with tasks like tire changes or engine assembly. This not only speeds up the process but also minimizes the risk of injury from lifting heavy parts. Additionally, robots can work in hazardous environments, such as areas with high temperatures or toxic fumes, keeping human workers safe.

However, integrating robotics into a workshop requires careful planning and investment. Workshops need to ensure that their staff is trained to operate and maintain these systems. Moreover, the initial cost can be high, but the long-term benefits in terms of productivity and safety often justify the investment.

Smart Tools

Another exciting development is the rise of smart tools—equipment embedded with sensors, connectivity, and sometimes even AI capabilities. These tools can provide real-time feedback, track usage, and even predict maintenance needs.

For instance, a smart torque wrench might connect to a mobile app, allowing users to set precise torque values and receive alerts when the desired torque is reached. This ensures that bolts are tightened correctly, reducing the risk of over-tightening or under-tightening.

Similarly, smart diagnostic tools can analyze data from vehicles or machinery, identifying issues before they become serious problems. This predictive maintenance can save time and money by preventing breakdowns and extending the lifespan of equipment.

Smart tools also enhance training and skill development. For example, a smart soldering iron could guide a novice through the soldering process, providing tips and corrections in real time.

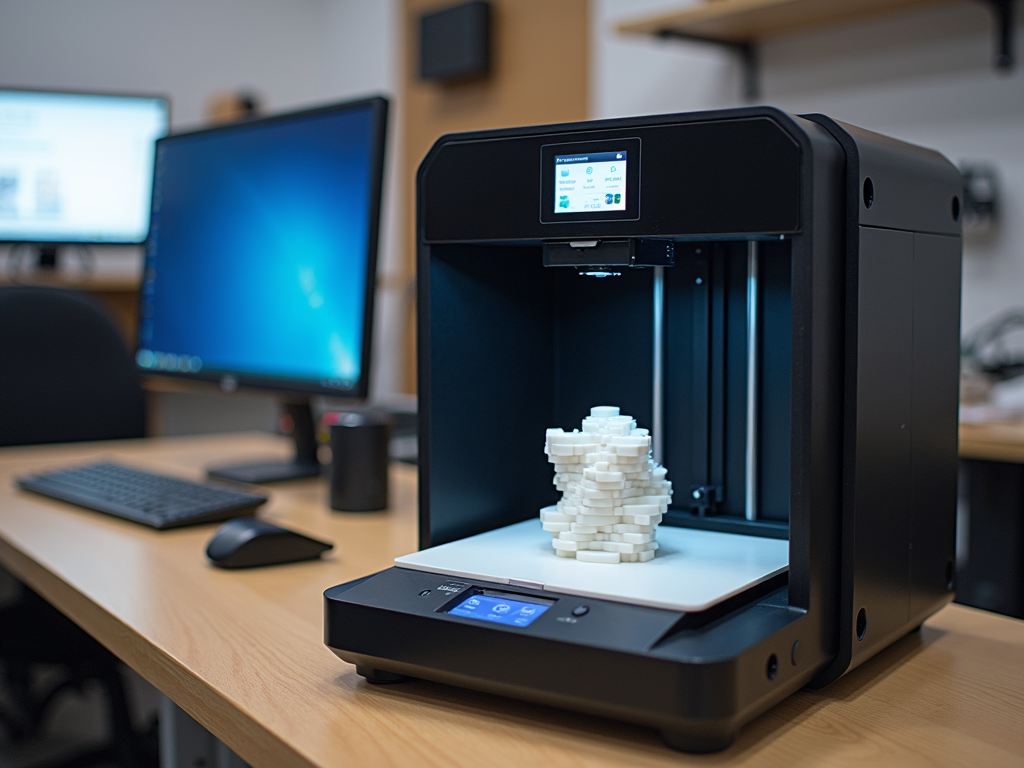

3D Printing

3D printing, or additive manufacturing, is revolutionizing how workshops create and repair parts. With a 3D printer, workshops can produce custom tools, replacement parts, or prototypes on-demand, reducing lead times and costs.

For example, if a specific tool is needed for a unique job, instead of ordering it and waiting for delivery, a workshop can design and print it in-house. This flexibility is particularly valuable for small businesses or specialized workshops.

Moreover, 3D printing allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for innovative tool designs.

However, 3D printing also requires expertise in design software and an understanding of material properties. Workshops need to invest in training and possibly hire skilled personnel to fully leverage this technology.

AR and VR in Workshops

Augmented Reality (AR) and Virtual Reality (VR) are finding their way into workshops, offering new ways to train staff, simulate processes, and provide remote assistance.

AR can overlay digital information onto the physical world, helping technicians visualize complex assemblies or receive step-by-step instructions. For instance, a mechanic wearing AR glasses could see a virtual diagram of an engine while working on it, highlighting which parts to remove or adjust.

VR, on the other hand, can create immersive training environments where workers can practice skills without the risk of damaging real equipment. This is particularly useful for high-stakes or dangerous tasks.

Additionally, AR and VR can facilitate remote collaboration. An expert from another location can guide a technician through a repair using AR annotations or a shared VR space.

Sustainability in Workshop Equipment

As environmental concerns grow, workshops are increasingly adopting sustainable practices and equipment. This includes using energy-efficient machinery, recycling materials, and choosing eco-friendly products.

For example, workshops might invest in solar-powered tools or equipment that consumes less energy. They might also implement waste reduction strategies, such as reusing or recycling metal shavings and other byproducts.

Moreover, there's a growing demand for tools made from sustainable materials, such as biodegradable plastics or recycled metals. Manufacturers are responding by developing greener alternatives without compromising performance.

Sustainability not only benefits the environment but can also lead to cost savings through reduced energy consumption and waste disposal fees.

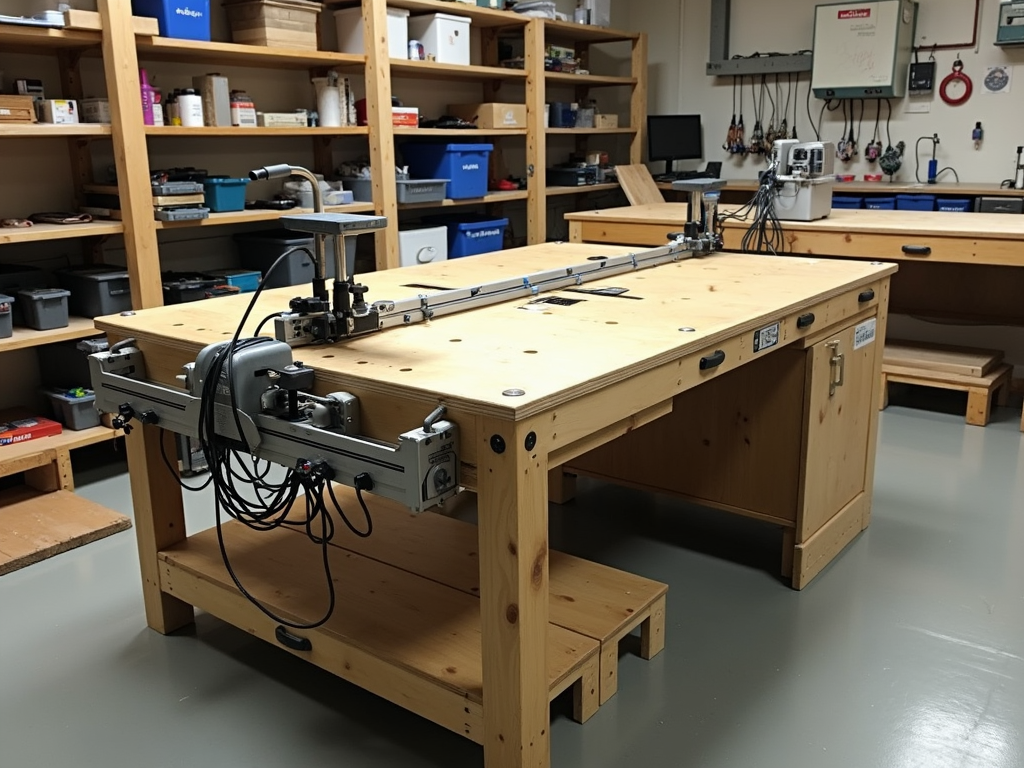

Modular and Flexible Equipment

The future of workshop equipment also lies in modularity and flexibility. Modular equipment can be easily reconfigured or upgraded to adapt to different tasks or new technologies.

For instance, a workbench with interchangeable modules for different tools or functions allows workshops to customize their setup based on current needs. Similarly, modular storage systems can be expanded or reorganized as the workshop grows.

This flexibility is crucial in a rapidly changing industry, where new tools and techniques are constantly emerging. It also helps workshops maximize their space and resources.

Safety Enhancements

Safety is always a top priority in workshops, and future equipment is likely to include even more advanced safety features. This could involve sensors that detect potential hazards, automatic shut-off mechanisms, or wearable devices that monitor workers' health.

For example, a power tool might have a sensor that stops the blade if it detects proximity to skin, preventing accidents. Similarly, workshops might use IoT devices to monitor air quality or noise levels, ensuring a safe working environment.

Training and education will also play a crucial role in safety. Workshops need to ensure that all staff are aware of the latest safety protocols and how to use new equipment properly.

Integration with Software

Modern workshops are increasingly relying on software to manage operations, from inventory tracking to customer relations. Future workshop equipment will likely be designed to integrate seamlessly with these software systems.

For instance, tools might automatically log usage data into a maintenance schedule, or diagnostic equipment could directly update a vehicle's service record in the workshop's database.

This integration streamlines workflows, reduces paperwork, and helps workshops make data-driven decisions. However, it also requires robust cybersecurity measures to protect sensitive information.

The future of workshop equipment is bright, with innovations that promise to make work safer, more efficient, and more sustainable. From automation and smart tools to 3D printing and AR/VR, these trends are transforming how workshops operate. By staying informed and adopting these technologies, workshops can improve their productivity, reduce costs, and provide better services to their customers. As we look ahead, it's clear that the workshops of tomorrow will be more connected, intelligent, and adaptable than ever before.

Related The Future of Workshop Equipment: Trends to Watch:

- Top 10 Innovative Workman Tools in 2024

- The Role of Technology in Modern Workshops

- How to Pick the Perfect Screwdriver for Any Task

- A Simple Guide to Your Home’s Electrical Setup

- DIY Projects for Beginners: Getting Started with Basic Tools

- Safety First: Protecting Yourself in the Metalworking Shop

- Breaking It Down

- Ultimate Guide to Mobile Storage Carts for Tools

- Tool Maintenance: Tips for Longevity

- The History of Black & Decker: Pioneers of Power Tools

- The Benefits of Using a Rotary Tool: A Must-Have for Every Craftsman

- Essential Tools Every Workman Must Have: A Comprehensive Guide