Metalwork is a craft that requires precision, skill, and the right tools. Whether you're a professional metalworker or a hobbyist, having the right specialized workman tools can make all the difference in the quality of your work. In this guide, we'll explore the essential tools every metalworker should have, from toolboxes to specific workman tools, and share insights from experienced craftsmen to help you elevate your metalworking projects.

Introduction to Metalwork and the Importance of Specialized Tools

Metalwork is an ancient craft that has evolved over centuries, from the forging of swords and armor to the creation of intricate jewelry and modern machinery. At its core, metalwork involves shaping and manipulating metal to create functional or decorative objects. This can include processes such as cutting, bending, welding, and finishing.

One of the key factors that determine the success of a metalworking project is the tools used. Specialized workman tools are designed to perform specific tasks with precision and efficiency, making them indispensable for metalworkers. These tools not only enhance the quality of the work but also improve safety and reduce the time and effort required to complete a project.

In this section, we'll delve into the world of metalwork and explore why specialized tools are crucial for achieving professional results.

Essential Specialized Workman Tools for Metalwork

In this section, we'll explore the must-have tools for any metalworker, categorized by their primary functions: cutting, shaping, joining, and measuring and marking.

Cutting Tools

Cutting tools are essential for removing material and shaping metal. Some of the most common cutting tools used in metalwork include:

- Hacksaws: Ideal for cutting through metal bars, rods, and pipes.

- Shears: Used for cutting sheet metal and thin plates.

- Angle Grinders: Versatile tools for cutting, grinding, and polishing metal.

- Plasma Cutters: Advanced tools for precise and fast cutting of thick metal sheets.

Shaping Tools

Shaping tools are used to bend, form, and manipulate metal into desired shapes. Key shaping tools include:

- Hammers: Various types, such as ball-peen and cross-peen hammers, for shaping and riveting.

- Anvils: Sturdy surfaces for hammering and shaping metal.

- Bending Brakes: Machines for bending sheet metal into precise angles.

- Rollers: Used for curving metal sheets and bars.

Joining Tools

Joining tools are crucial for connecting metal pieces together. Common joining tools include:

- Welding Machines: For fusing metal pieces using heat and filler material.

- Soldering Irons: Used for joining metal with a lower melting point filler.

- Rivet Guns: For fastening metal sheets with rivets.

- Clamps: Essential for holding metal pieces in place during joining.

Measuring and Marking Tools

Accurate measurement and marking are vital for precise metalwork. Essential tools include:

- Calipers: For measuring internal and external dimensions.

- Micrometers: For highly accurate measurements.

- Squares: For ensuring right angles and straight lines.

- Marking Gauges: For scribing lines on metal surfaces.

Toolboxes for Metalwork: Organization and Efficiency

A well-organized toolbox is a metalworker's best friend. It not only keeps tools safe and accessible but also enhances efficiency by reducing the time spent searching for the right tool. When choosing a toolbox for metalwork, consider the following factors:

- Size and Capacity: Ensure the toolbox can accommodate all your essential tools.

- Durability: Look for sturdy materials that can withstand the rigors of a workshop environment.

- Portability: If you need to transport your tools, opt for a toolbox with wheels or a comfortable handle.

- Organization: Choose a toolbox with compartments and trays to keep tools neatly arranged.

In this section, we'll explore different types of toolboxes suitable for metalwork and share tips on how to organize your tools effectively.

Tips and Tricks from Experienced Metalworkers

Learning from those who have mastered the craft can significantly improve your metalworking skills. Here are some valuable tips and tricks from experienced metalworkers:

- Always wear appropriate safety gear, including gloves, goggles, and ear protection.

- Keep your tools clean and well-maintained to ensure optimal performance.

- Practice on scrap metal before working on your actual project to perfect your techniques.

- Use the right tool for the job to avoid damaging the metal or the tool.

- Take your time and work methodically to achieve precise results.

By incorporating these tips into your metalworking practice, you can enhance your skills and produce higher-quality work.

Conclusion: Elevating Your Metalwork with the Right Tools

In conclusion, specialized workman tools are essential for achieving professional results in metalwork. From cutting and shaping to joining and measuring, each tool plays a crucial role in the metalworking process. Additionally, a well-organized toolbox can significantly improve your efficiency and productivity.

By investing in high-quality tools and learning from experienced craftsmen, you can elevate your metalworking projects and take your skills to the next level.

Related specialized workman tools for metalwork:

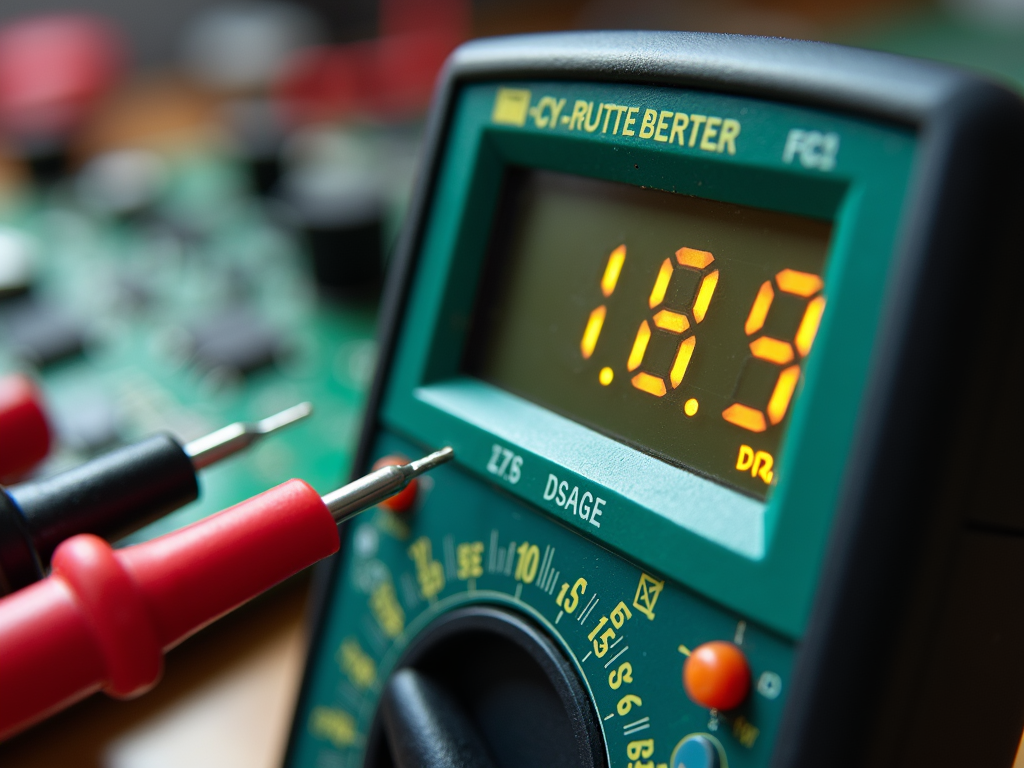

- Choosing the Right Multimeter for Your Needs: A Comprehensive Guide

- Organizing Your Toolbox: Tips and Tricks for Every Handyman

- The Importance of Quality Tools in DIY Projects

- Essential Chisels in a Woodworker’s Toolkit: Your Guide to the Best Tools

- Essential Safety Tips for Your Home Workshop

- Stay Safe: Essential Safety Practices for Workman Tools

- Picking the Perfect Drill Bit for Any Job

- Unleash Your Creativity: Rotary Tools for Sanding, Polishing, and Beyond

- The Ultimate Guide to Hand Tools Every Mechanic Needs

- Top 10 Hand Tools Every Workman Should Own

- How to Choose the Right Power Washer for Your Needs

- Essential Electrical Tools for Troubleshooting and Repair: A Comprehensive Guide