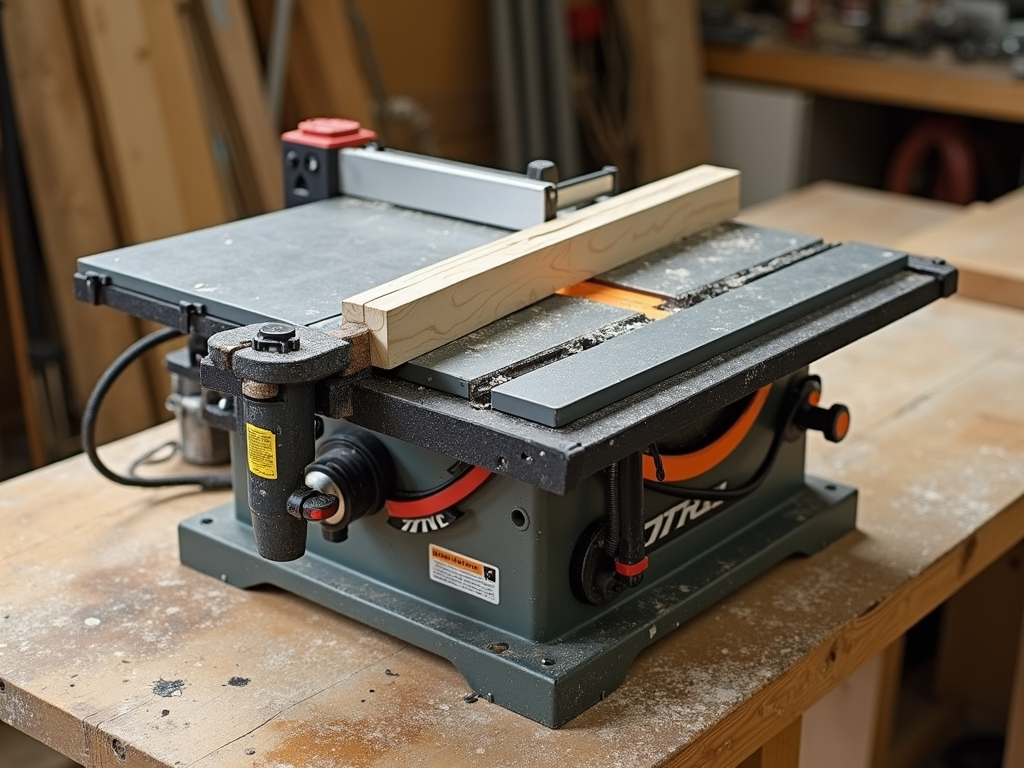

Tablesaws are powerful tools that can transform woodworking projects, but they come with risks. Advanced safety mechanisms like blade guards and riving knives help prevent accidents, making these power tools safer for everyone.

Why Safety Matters in Tablesaws

Tablesaws with advanced safety mechanisms are game-changers for woodworkers. These features reduce the chance of injury by stopping common problems like kickback or accidental blade contact. Let’s explore how they work and why they’re essential.

Blade Guards: Your First Line of Defense

A blade guard covers the spinning blade when it’s not cutting. It’s usually clear plastic or metal and keeps your hands away from danger. Plus, it traps sawdust, keeping your workspace cleaner. I’ve seen these guards stop small mistakes from turning into big injuries.

Riving Knives: Preventing Kickback

A riving knife is a thin metal piece behind the blade. It stops the wood from pinching the blade, which can cause kickback—when the wood flies back at you. I learned this the hard way once when a board kicked back and hit me. Now, I never cut without one.

Anti-Kickback Pawls: Extra Protection

These are small, sharp teeth that grab the wood if it starts moving backward. They work with the riving knife to keep things steady. They’re simple but effective, especially on tricky cuts.

Types of Blade Guards

Not all blade guards are the same. Overhead guards hang above the blade, offering full coverage. Modular guards snap off easily for quick changes. I prefer modular ones because they’re flexible for different projects.

A Personal Lesson

Years ago, I skipped the riving knife to save time. Halfway through a cut, the wood shot back and bruised my ribs. It was a wake-up call. Since then, I’ve made safety my priority, and these mechanisms have saved me more than once.

Training Makes a Difference

Even the best tablesaws with advanced safety mechanisms won’t help if you don’t know how to use them. Take time to learn. Watch tutorials or take a class. Understanding your tool builds confidence and keeps you safe.

Maintenance Tips

Check your safety features often. A loose blade guard or dull riving knife won’t protect you. Clean them after every project and replace anything worn out. It’s a small effort for big peace of mind.

Choosing the Right Tablesaw

When buying a tablesaw, look for built-in safety features. Some brands, like SawStop, even stop the blade if it touches skin. They cost more, but they’re worth it if you value your fingers.

Common Mistakes to Avoid

Don’t remove safety gear for convenience—it’s not worth the risk. Always wear goggles and ear protection too. I’ve seen friends skip these steps and regret it after a close call.

Safety Stats

According to the Consumer Product Safety Commission, tablesaw accidents send thousands to the ER yearly. Advanced safety mechanisms could cut that number down. It’s not just about tools—it’s about using them right.

Final Thoughts

Tablesaws with advanced safety mechanisms turn a risky tool into a reliable one. Blade guards, riving knives, and anti-kickback pawls work together to protect you. With training and care, you can enjoy woodworking without worry.

Related tablesaws with advanced safety mechanisms:

- How to Choose the Right Wrench for Your Project

- How to Organize Your Workshop for Maximum Efficiency

- Tool Organization Tips for Painters: Boost Your Efficiency and Creativity

- Essential Tools for Every Workman's Toolbox: A Comprehensive Guide

- Best Power Tools for DIY Beginners

- Mastering Workshop Tool Maintenance: A Pro's Guide to Long-Lasting Gear

- Sustainable Practices in Modern Workshops

- Power Tools Safety Guidelines: A Comprehensive Guide

- Mastering Advanced Techniques for Professional Woodworkers

- Must-Have Safety Gear for DIY Projects: Stay Protected While You Create

- Healthy Habits for Hard-Working Tradespeople: Staying Safe and Comfortable on the Job

- Power Tools Maintenance Tips: Keep Your Gear in Top Shape