Tools are essential for any job, whether you’re fixing a car, crafting furniture, or tackling a home project. Keeping them in good condition saves money and boosts performance. Here are the top maintenance tips for extending tool lifespan, covering workman tools, woodworking tools, and more—all in one handy guide.

Why Tool Maintenance Matters

Maintaining tools isn’t just about making them last longer—it’s about safety and efficiency too. A well-cared-for tool works better and reduces the chance of accidents. I’ve learned this the hard way: once, I left a wrench covered in grease overnight, and by morning, it had a rust spot. Simple care can prevent that.

Clean Your Tools After Every Use

Cleaning is the easiest step to extend tool life. Dust, grease, and debris wear down metal over time. For workman tools like hammers or screwdrivers, a quick wipe with a dry cloth does the trick. For greasy workman tools for automotive repair, I use a rag with a bit of soap and water. It takes five minutes but saves years of use.

For woodworking tools, sawdust is the enemy. It holds moisture against blades, inviting rust. I brush off my saws and chisels after every project. If there’s sticky sap, a little rubbing alcohol cleans it right up. Trust me, clean tools feel better in your hands too.

Store Tools the Right Way

Where you keep your tools matters as much as how you use them. Moisture and heat are silent killers—rust can form overnight in a damp shed. I store my workman tools in a toolbox with a tight lid. For woodworking tools, I hang them on a pegboard in my shop. It keeps them dry and easy to find.

Here’s a quick storage checklist:

- Dry spot: Avoid basements or garages with leaks.

- Toolbox or rack: Protect tools from banging into each other.

- Silica packs: Toss these in for extra moisture control.

Good storage keeps tools ready when you need them.

Lubricate Moving Parts

Tools with hinges or gears—like pliers or ratchets—need lubrication to stay smooth. Friction wears them out fast. I dab a little machine oil on the pivot of my pliers every few months. For workman tools for automotive repair, like ratchets, I oil the mechanism lightly and wipe off extra to avoid dirt buildup.

Power tools need love too. Check the manual for where to lubricate—usually gears or bearings. I learned this after a drill started squeaking; a drop of oil fixed it right up. It’s a small step that keeps tools running like new.

Keep Cutting Tools Sharp

Dull blades are dangerous—they slip and take more effort to use. For woodworking tools like chisels or saws, sharpening is a must. I use a whetstone for my chisels, running the edge at a steady angle. It’s satisfying to see the blade gleam again.

Saws need attention too. I file the teeth of my hand saws every few months—carefully, so they cut straight. For power saws, I take them to a pro. Sharp tools make cleaner cuts and last longer, plain and simple.

Check Power Tools Regularly

Power tools have more parts, so they need extra care. I always check cords for cuts or fraying—once, I caught a nick just before it got worse. For cordless tools, I make sure batteries aren’t overcharged and store them cool and dry.

Here’s a power tool maintenance list:

| Task | How Often | Why It Helps |

|---|---|---|

| Check cords | Monthly | Prevents shocks |

| Clean vents | After each use | Keeps motor cool |

| Replace brushes | As needed | Maintains power |

A quick check can stop big problems.

Use Tools the Right Way

Using tools wrong is a fast track to breaking them. I’ve bent a screwdriver prying something open—lesson learned. For workman tools for automotive repair, match the wrench size to the bolt. Twisting too hard strips threads and ruins the tool.

In woodworking, don’t force a chisel through knotty wood—it’ll chip. Use the right tool for each task, and they’ll thank you by lasting longer. It’s about respect for the craft and the gear.

Tips for Automotive Tools

Workman tools for automotive repair—like sockets and wrenches—face tough conditions. Grease and oil are everywhere. I wipe mine down after every job with a degreaser, then oil the ratchets lightly. Storing them in a toolbox keeps them safe and organized.

Once, I lost a socket because I left it loose in my garage. Now, I double-check everything goes back where it belongs. It’s a habit that pays off.

Caring for Woodworking Tools

Woodworking tools need special attention. Saws and planes dull fast if you skip maintenance. I sharpen my plane blade monthly and clean off resin with a cloth. Hanging them up keeps rust away—woodshops can get humid.

I’ve had a chisel last 10 years because I don’t let it sit dirty. It’s worth the effort when you feel it slice through wood like butter.

Mistakes to Avoid

Even small slip-ups can hurt your tools. Don’t skip cleaning—rust sneaks up fast. Storing tools in a wet spot is asking for trouble. I once used car oil on a saw blade, and it gummed up—stick to light machine oil instead.

Ignoring dull blades or loose handles is another no-no. Fix little issues before they grow. It’s easier to sharpen a saw than replace it.

Wrapping It Up

These top maintenance tips for extending tool lifespan—cleaning, storing, lubricating, sharpening, checking, and using tools right—keep your gear in top shape. Whether it’s workman tools for automotive repair or woodworking tools, a little effort goes far. I’ve seen my tools last decades with this care, and yours can too.

Related Top Maintenance Tips for Extending Tool Lifespan:

- Essential Safety Checks for Power Tools

- Essential Safety Gear for Power Tool Users

- A Comprehensive Guide to Workwear and Safety Gear

- Top 10 Sustainable Hand Tools in 2024

- Top 10 Plumbing Tools Every DIYer Should Own

- Mastering Power Tool Maintenance: Keep Your Tools Running Like New

- Safety Tips for Using Power Tools: The Ultimate Guide to Cordless Drill Care

- The Difference Between Automotive and Manual Tools

- Choosing the Right Wrench for Your Projects: A Comprehensive Guide

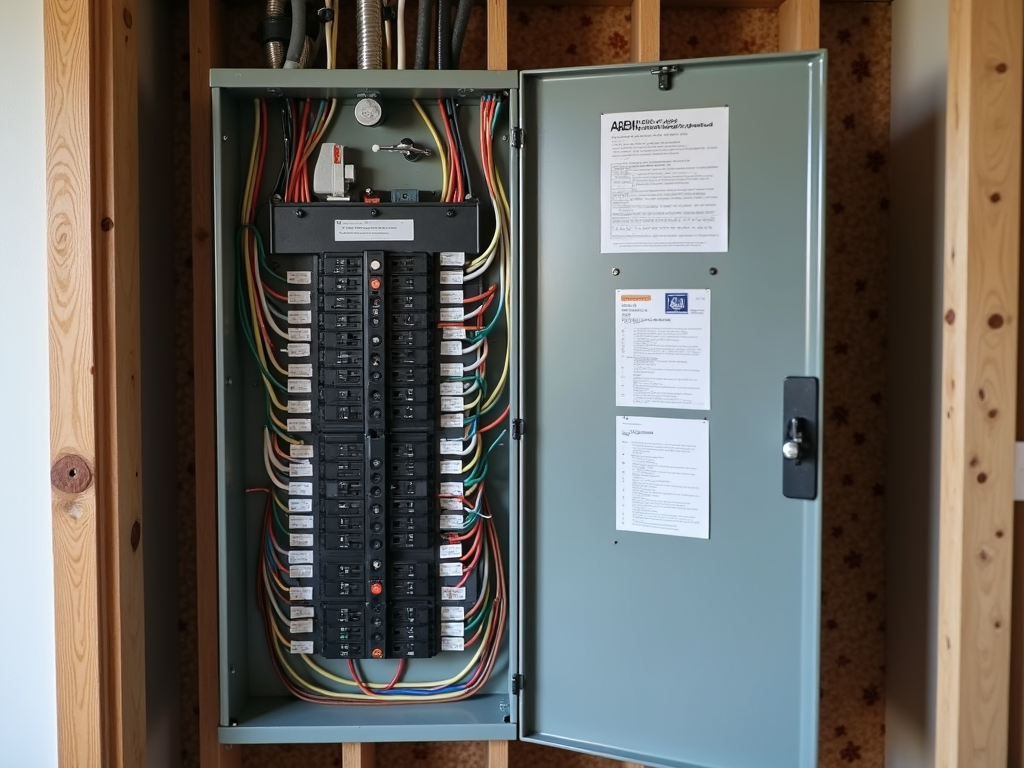

- A Simple Guide to Your Home’s Electrical Setup

- Beginner’s Guide to Woodworking: Essential Tools, Safety Tips, and Simple Projects

- Essential Workman Tools for Plumbing Projects: A Comprehensive Guide