Overview: In the world of car repairs, precision is key. One tool that stands out for ensuring accuracy is the torque wrench. This specialized tool allows mechanics to tighten bolts and nuts to exact specifications, preventing the risks associated with over-tightening or under-tightening. In this article, we'll explore how torque wrenches improve accuracy in car repairs, the different types available, and best practices for their use.

What is a Torque Wrench?

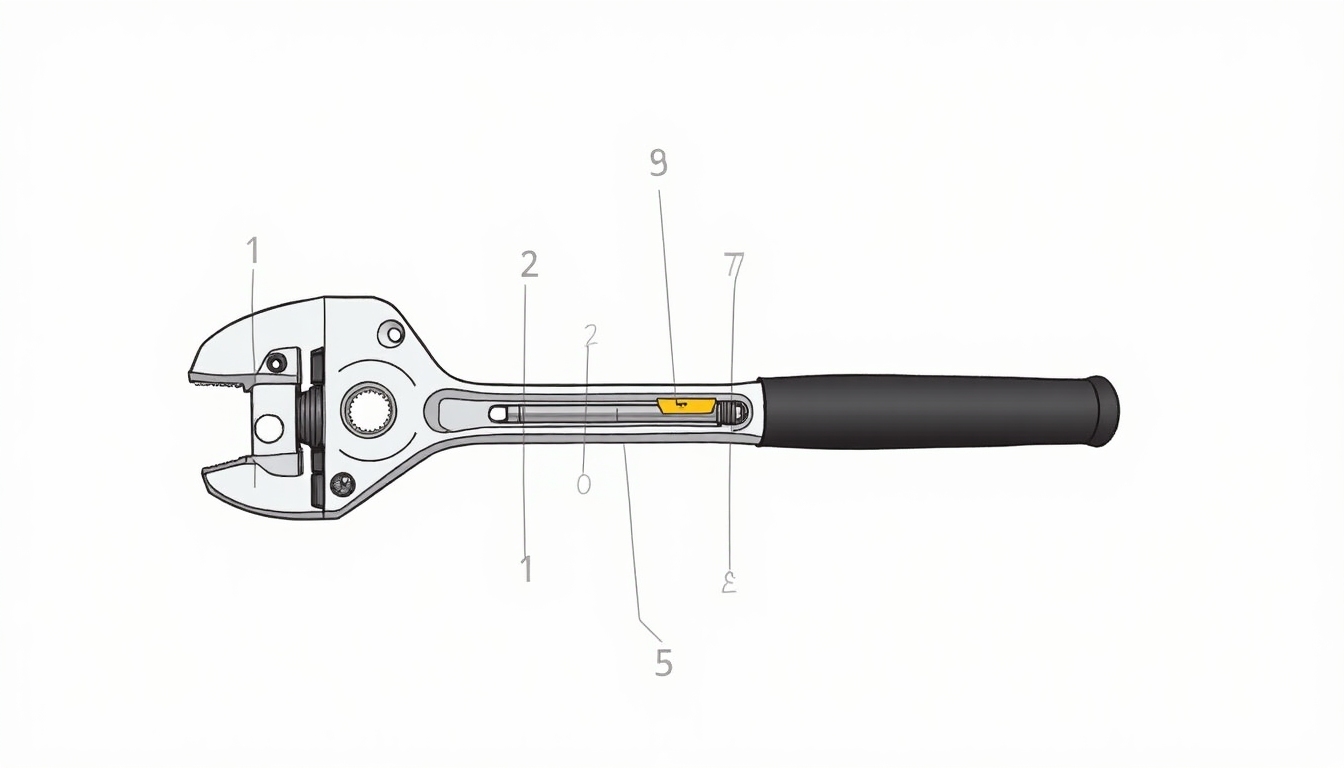

A torque wrench is a precision tool designed to apply a specific amount of torque to a fastener, such as a nut or bolt. Unlike standard wrenches, which rely on the user's judgment, torque wrenches provide a measurable way to ensure that fasteners are tightened correctly. This is crucial in automotive repairs, where the correct torque can mean the difference between a safe, reliable vehicle and one prone to mechanical failures.

Importance of Accuracy in Car Repairs

Accuracy in car repairs is not just about doing the job right; it's about safety. When fasteners are not tightened to the correct torque, several issues can arise:

- Over-Tightening: This can strip the threads of bolts or nuts, making them difficult to remove or reuse. In severe cases, it can cause the fastener to break, leading to part failure.

- Under-Tightening: If a fastener is not tight enough, it can loosen over time due to vibrations, potentially causing parts to detach while the vehicle is in motion.

Both scenarios can have serious consequences, especially for critical components like wheels, suspension parts, or engine components.

| Consequence | Over-Tightening | Under-Tightening |

|---|---|---|

| Fastener Damage | Stripped threads, broken bolts | Loosening over time |

| Safety Risks | Part failure under stress | Parts detaching while driving |

| Performance Issues | Misalignment, imbalance | Vibrations, noise |

Understanding these risks highlights why using a torque wrench is essential for any mechanic aiming to provide high-quality repairs.

How Torque Wrenches Improve Accuracy

Torque wrenches improve accuracy by allowing mechanics to set a precise torque value before tightening a fastener. Once the set torque is reached, the wrench provides feedback—typically a click, a beep, or a visual indicator—alerting the user to stop applying force. This eliminates guesswork and ensures consistency across all fasteners.

For example, when installing a wheel, each lug nut must be tightened to the same torque to ensure even pressure distribution. A torque wrench makes this possible, reducing the risk of warping the brake rotor or causing uneven tire wear.

Types of Torque Wrenches

There are several types of torque wrenches, each with its own advantages and best-use scenarios:

- Beam Torque Wrench: This is the most basic type, consisting of a handle attached to a beam with a scale. As torque is applied, the beam bends, and the scale indicates the torque value. While affordable, it requires the user to watch the scale carefully, which can be less precise.

- Click Torque Wrench: The most popular type among mechanics, it allows the user to set a specific torque value. When that value is reached, the wrench emits a click sound, indicating it's time to stop. It's user-friendly and suitable for most automotive applications.

- Digital Torque Wrench: This modern variant features a digital display that shows the exact torque being applied. Some models can also store torque data or connect to devices for record-keeping. While more expensive, it offers high precision and is ideal for professional use.

-

Dial Torque Wrench: Similar to the beam type but with a dial gauge for reading torque. It's useful for applications where continuous monitoring of torque is necessary, such as in assembly lines.

-

Beam Torque Wrench: Basic, affordable, requires careful observation.

- Click Torque Wrench: Popular, easy to use, audible feedback.

- Digital Torque Wrench: High precision, digital display, advanced features.

- Dial Torque Wrench: Continuous monitoring, dial gauge.

Tips for Using a Torque Wrench

Using a torque wrench correctly is crucial for achieving accurate results. Here are some essential tips:

- Consult the Manual: Always refer to the vehicle's service manual for the correct torque specifications. Different fasteners require different torque values.

- Calibrate Regularly: Torque wrenches can lose accuracy over time. Have them calibrated periodically to ensure they provide precise measurements.

- Apply Torque Smoothly: When using the wrench, apply force in a smooth, steady motion. Jerky movements can lead to inaccurate torque application.

- Store Properly: After use, set the wrench to its lowest torque setting and store it in a protective case to prevent damage.

- Avoid Using Extensions: Extensions can alter the effective length of the wrench, affecting the torque applied. If necessary, use extensions designed for torque wrenches and adjust calculations accordingly.

Common Mistakes to Avoid

Even with the best tools, mistakes can happen. Here are some common errors to avoid when using a torque wrench:

- Ignoring Specifications: Not checking the correct torque value for each fastener can lead to improper tightening.

- Using a Damaged Wrench: A wrench that's been dropped or mishandled may not provide accurate readings. Inspect your tool regularly.

- Overloading the Wrench: Applying more torque than the wrench is rated for can damage the tool and lead to inaccurate results.

- Incorrect Angle: Holding the wrench at an angle can affect the torque applied. Always keep the wrench perpendicular to the fastener.

Summary: In conclusion, torque wrenches are indispensable tools for any mechanic serious about accuracy and safety in car repairs. By understanding how they work, choosing the right type for the job, and following best practices, you can ensure that every fastener is tightened to perfection. Remember, precision in repairs not only enhances vehicle performance but also ensures the safety of drivers and passengers alike.

Related How Torque Wrenches Improve Accuracy in Car Repairs:

- Common Workshop Tool Problems and Solutions: A Guide to Screwdriver Maintenance and More

- Must-Have Hand Tools for Mechanics: A Comprehensive Guide

- The Ultimate Guide to Tool Belts with Ergonomic Designs

- Essential Workman Tools: Must-Haves for Every Toolbox

- Mastering Rotary Tool Accessories and Attachments

- The Ultimate Guide to Power Tools for Woodworking Enthusiasts

- Top Screwdriver Maintenance Tips

- Power Washer Maintenance Tips

- Features to Look for in a Workbench

- Essential Tool Maintenance and Care Tips

- Choosing the Right Hammer for Your Projects

- The Essential Guide to Electrical Tools