Tools are the backbone of any construction project, but they need care to perform at their best. In this ultimate guide, we'll walk you through the essentials of tool maintenance, sharing tips and tricks to help you get the most out of your equipment.

Why Tool Maintenance Matters

Whether you're a beginner building your first construction tool kit or a seasoned professional, understanding how to maintain your tools is essential. Well-maintained tools not only last longer but also perform better and are safer to use. I remember when I was working on a project and my wrench slipped because it was rusty. It not only delayed the work but also posed a safety risk. That's when I realized the importance of regular tool maintenance.

Proper maintenance can save you money in the long run by reducing the need for replacements and preventing accidents that could lead to costly injuries.

General Cleaning and Care

The first step in tool maintenance is keeping them clean. After each use, wipe down your tools with a clean cloth to remove dirt and debris. For tougher grime, use a mild detergent and water, but make sure to dry them thoroughly to prevent rust.

Lubrication is also key. Applying a light coat of oil to metal parts can prevent rust and keep moving parts functioning smoothly. For tools with gears or hinges, use a appropriate lubricant as recommended by the manufacturer.

Regularly inspect your tools for signs of wear and tear, such as cracks, bends, or dull edges. Addressing these issues early can prevent further damage.

Special Focus: Maintaining Your Wrench Set

Wrenches are a staple in any workman's toolkit, and having a good set is crucial for construction workers. To keep your wrenches in optimal condition, follow these tips:

- Clean them after each use to remove grease and dirt.

- Check for any signs of wear, especially on the jaws or adjustment mechanisms.

- For adjustable wrenches, ensure the adjustment knob moves smoothly; lubricate if necessary.

- Store them in a dry place, preferably hanging or in a toolbox to prevent damage.

If you've invested in one of the best wrench sets for construction workers, regular maintenance will ensure it serves you well for years.

Other Hand Tools

Hammers: Check the handle for cracks or splinters, and ensure the head is securely attached. If the handle is wooden, you can sand it lightly and apply a coat of linseed oil to protect it.

Screwdrivers: Keep the tips clean and in good shape. If the tip becomes worn or rounded, it may need to be replaced or reshaped.

Pliers: Lubricate the pivot point to keep them opening and closing smoothly. Check for any bending or damage to the jaws.

Maintaining Power Tools

Power tools require more specific maintenance, often according to the manufacturer's instructions. Here are some general tips:

- Drills: Clean the chuck and check for any debris. Inspect the brushes and replace if worn.

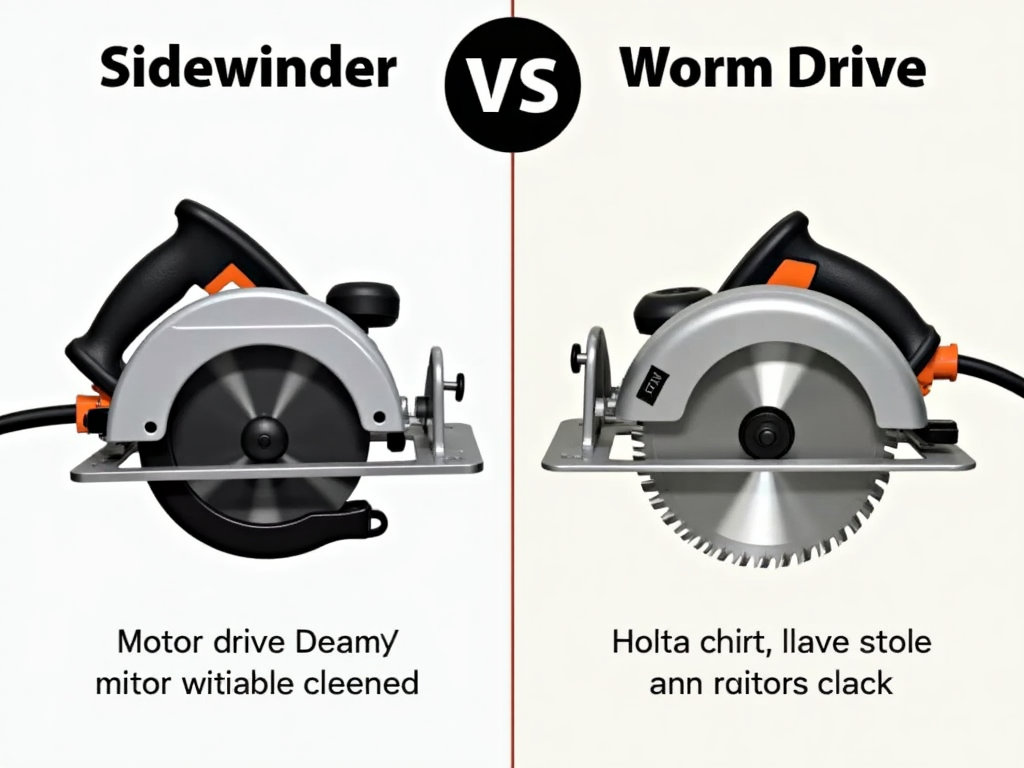

- Saws: Keep the blade sharp and clean. Lubricate any gears or moving parts.

- Sanders: Replace sandpaper regularly and clean the dust collection system.

Always unplug power tools before performing any maintenance. Refer to the user manual for detailed instructions.

| Tool | Maintenance Task |

|---|---|

| Drill | Clean chuck, check brushes |

| Saw | Sharpen blade, lubricate gears |

| Sander | Replace sandpaper, clean dust collection |

Storage Solutions

Proper storage is crucial to prevent damage and rust. Here are some tips:

- Use a toolbox or pegboard to keep tools organized and easily accessible.

- Store tools in a dry place to prevent moisture buildup.

- Consider using silica gel packs in your toolbox to absorb excess moisture.

- For power tools, remove batteries and store them separately if not in use for extended periods.

Safety First

Maintaining your tools isn't just about longevity; it's also about safety. Dull blades, loose handles, or damaged cords can lead to accidents. Always inspect your tools before use, and never use a tool that appears damaged. Remember, a well-maintained tool is a safe tool.

Common Mistakes to Avoid

- Neglecting regular maintenance: Set a schedule to clean and inspect your tools periodically.

- Using the wrong cleaning agents: Avoid harsh chemicals that can damage tool finishes.

- Improper storage: Don't leave tools exposed to the elements or in damp areas.

DIY Maintenance Hacks

- Remove rust with vinegar: Soak rusty tools in white vinegar overnight, then scrub with a wire brush.

- Homemade lubricant: Mix equal parts of vegetable oil and acetone for a budget-friendly lubricant.

- Clean battery terminals: Use a mixture of baking soda and water to clean corroded battery terminals on power tools.

Conclusion

Tool maintenance might seem like a chore, but it's an investment in your safety and efficiency. By following the tips in this guide, you can extend the life of your tools and ensure they perform at their best. Make tool maintenance a regular part of your routine, and you'll reap the benefits on every project.

Related The Ultimate Guide to Tool Maintenance:

- Safety Tips for DIY Auto Repair: A Comprehensive Guide

- Comprehensive Guide to Circular Saws for Beginners

- Essential Electrical Tools for Wiring and Installations

- How to Clean Your Deck with a Power Washer: A Step-by-Step Guide

- Top Ergonomic Power Drills for Reduced Fatigue

- Electric vs. Gas Power Washers: Which Wins?

- Rotary Tools for Jewelry Making: A Comprehensive Guide

- The Ultimate Guide to Power Tool Safety

- Care and Maintenance of Your Power Tools: A Guide for Woodworking Enthusiasts

- Key Features to Look for in Cordless Power Tools: Your Ultimate Guide

- A Beginner's Guide to Power Tools for Home Workshops: Essential Tools and Safety Tips

- The Complete Beginner’s Guide to Home Wiring