Overview

Torque is a fundamental concept in mechanics, especially in automotive repair. This article explains what torque is, why it matters, and how to use essential tools like wrenches to apply it correctly.

What is Torque?

Torque is a measure of the force that can cause an object to rotate. In simpler terms, it's the twisting force you apply when you turn a wrench to tighten a bolt. The amount of torque you apply determines how tightly the bolt is fastened. For mechanics, understanding torque is essential because it ensures that parts are secured properly without being damaged.

Why is Torque Important?

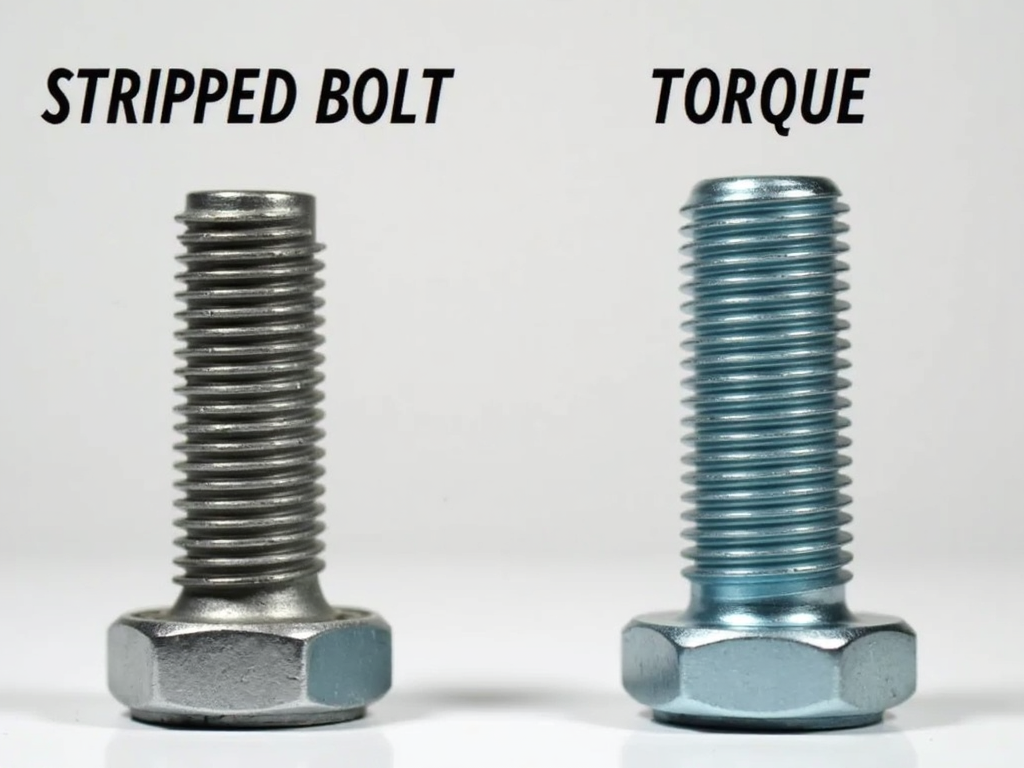

Applying the correct torque is crucial in automotive repair. If you don't apply enough torque, the bolt might come loose over time, leading to parts failing or even accidents. On the other hand, applying too much torque can strip the threads of the bolt or nut, making it difficult to remove later, or even break the bolt entirely. This is why mechanics must know how to use tools like wrenches properly to achieve the right balance.

I remember a time when I was helping a friend change the oil in his car. We were tightening the oil drain plug, and I didn't use a torque wrench. I thought I could just tighten it by feel. Well, I overtightened it and ended up stripping the threads. It was a costly mistake that could have been avoided if I had used the right tool and followed the proper torque specifications.

Essential Tools for Applying Torque: Wrenches

Wrenches are one of the most important tools for applying torque in automotive repair. There are several types of wrenches, each suited for different tasks. Below is a table comparing the most common types of wrenches and their uses:

| Type of Wrench | Description | Best For |

|---|---|---|

| Adjustable Wrench | Can be adjusted to fit different sizes of bolts and nuts | General use, when you don't have the exact size |

| Socket Wrench | Uses interchangeable sockets for different sizes | Working in tight spaces, quick changes |

| Torque Wrench | Applies a specific amount of torque | Precision tasks, like tightening lug nuts |

Among these, the torque wrench is particularly important because it allows you to apply a precise amount of torque, ensuring that you don't over- or under-tighten fasteners.

How to Use a Torque Wrench: Step-by-Step Guide

Using a torque wrench correctly is key to applying the right amount of torque. Here's a simple guide:

1. Select the correct torque setting based on the manufacturer's specifications. This information can usually be found in the vehicle's service manual or on the part itself.

2. Attach the appropriate socket to the torque wrench.

3. Place the socket over the bolt or nut.

4. Apply force to the handle of the wrench until you hear a click or see the indicator reach the set torque.

5. Stop applying force immediately to avoid overtightening.

Following these steps ensures that you apply the correct torque every time.

Common Torque Specifications in Automotive Repair

Different parts of a vehicle require different torque specifications. Here are some common examples:

- Lug nuts: Typically require between 80-100 ft-lbs of torque, depending on the vehicle.

- Oil drain plugs: Usually need around 20-30 ft-lbs.

- Spark plugs: Often require 15-20 ft-lbs.

Always check the specific torque requirements for the vehicle you're working on to avoid mistakes.

Understanding Units of Torque

Torque is measured in different units, most commonly foot-pounds (ft-lbs) and Newton-meters (Nm). It's important to know how to convert between these units, especially if you're working with tools or specifications from different regions. For example:

- 1 ft-lb = 1.356 Nm

- 1 Nm = 0.738 ft-lb

Many torque wrenches allow you to switch between units, but it's still useful to understand the conversion in case you need to make adjustments.

Practical Tips for Using Wrenches

Here are some additional tips to keep in mind when using wrenches:

- Always use the correct size wrench for the bolt or nut to avoid stripping it.

- Keep your wrenches clean and well-maintained to ensure they work properly.

- When using an adjustable wrench, make sure it's tightened properly on the fastener to prevent slipping.

- For socket wrenches, use the right socket size and ensure it's securely attached to the wrench.

These simple practices can help you avoid common mistakes and prolong the life of your tools.

Conclusion

In summary, understanding torque is essential for every mechanic. It's the key to ensuring that bolts and nuts are tightened correctly, preventing damage and ensuring safety. Using the right tools, like wrenches, and following proper procedures can make all the difference in automotive repair. Whether you're a seasoned professional or a DIY enthusiast, mastering torque will help you work more effectively and avoid costly mistakes.

Related Understanding Torque: Essentials for Every Mechanic:

- Must-Have Hand Tools for Mechanics: Your Essential Toolkit

- Enhancing Workshop Efficiency: Top Tips to Maximize Your Space

- How Technology is Making Workshops Safer

- How to Choose the Right Workman Tools for Your Project

- Tool Belts with Ergonomic Designs: A Game-Changer for Workman Tools

- Corded vs. Cordless: Which Power Tools Are Right for You?

- Mastering Metal Forming: Techniques and Tools

- Advanced Toolbox Organization Ideas for Every Handyman

- Must-Have Workman Tools for Every Toolbox: A Comprehensive Guide

- Top 5 Electric Power Washers for Home Use

- A Beginner’s Guide to Essential Construction Tools

- Understanding Nuts and Bolts for Repairs: A Complete Guide