Automation is transforming the electrical industry, and advanced tools are at the heart of this revolution. From programmable logic controllers to sophisticated sensors, these tools are making electrical work more efficient, precise, and safe. In this guide, we'll explore the key advanced electrical tools for automation, how they work, and why they're essential for modern electricians and technicians. Automation is not just a buzzword; it's a fundamental shift in how electrical work is performed. By leveraging these tools, you can achieve levels of precision and efficiency that were previously unimaginable.

What is Automation in Electrical Work?

Automation in electrical work involves using technology to control and monitor electrical systems with minimal human intervention. This can range from simple tasks like turning lights on and off based on motion sensors to complex industrial processes controlled by sophisticated software. The goal is to increase efficiency, reduce errors, and improve safety. At its core, automation relies on a closed-loop system consisting of inputs (sensors), logic (controllers like PLCs), and outputs (actuators).

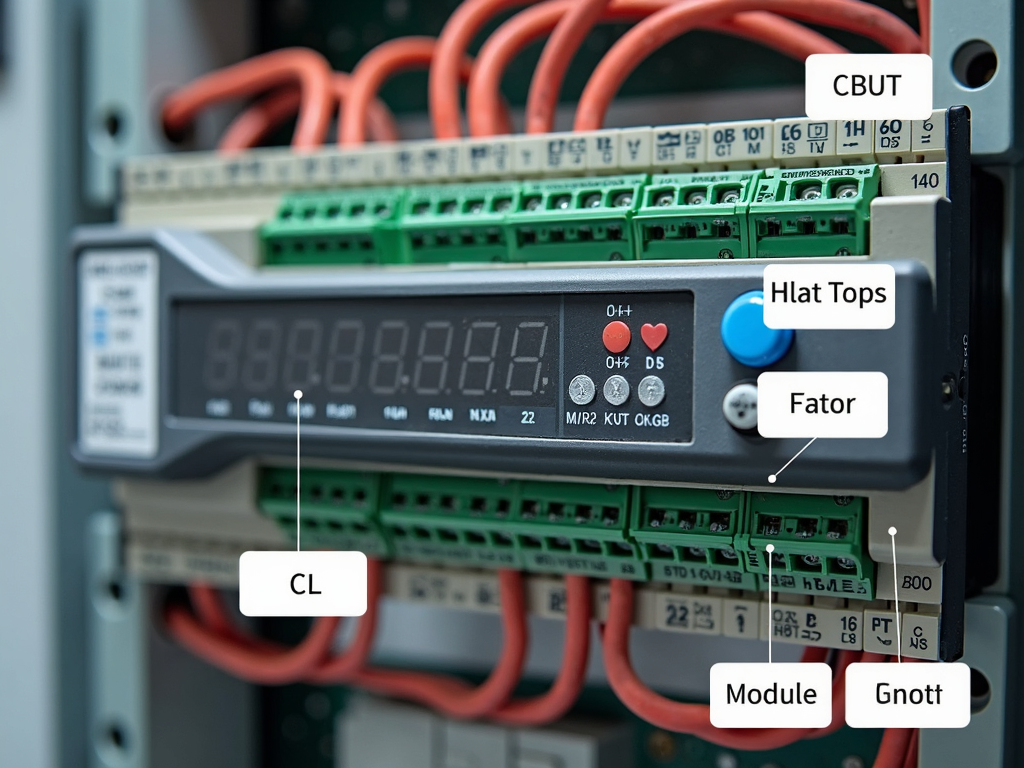

Programmable Logic Controllers (PLCs)

PLCs are the brains behind many automated systems. These digital computers are designed to control machinery and processes based on programmed instructions. They're highly reliable and can handle multiple inputs and outputs, making them ideal for complex automation tasks. PLCs can be programmed using languages like ladder logic, which resembles electrical schematics, making it intuitive for electricians. For example, the Allen-Bradley CompactLogix series is popular for its flexibility and ease of use.

Sensors

Sensors are crucial for automation as they provide the data that controllers use to make decisions. There are various types, including proximity sensors, temperature sensors, pressure sensors, and photoelectric sensors. For instance, in HVAC systems, temperature sensors help maintain comfortable indoor climates by automating heating and cooling. The choice of sensor depends on the specific application and the physical quantity being measured.

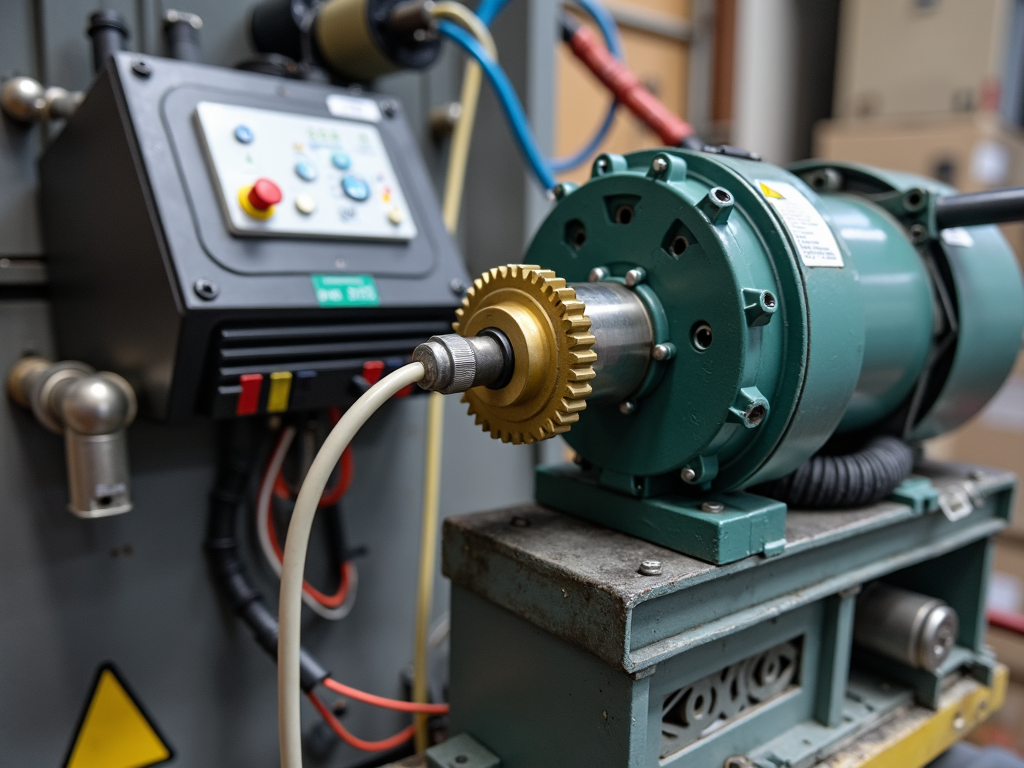

Actuators

Actuators are the output devices that perform actions based on controller commands. Common types include motors, solenoids, relays, and valves. In automated warehouses, for example, linear actuators move shelves or conveyor belts for efficient storage and retrieval. Actuators are essential for translating electrical signals into physical actions.

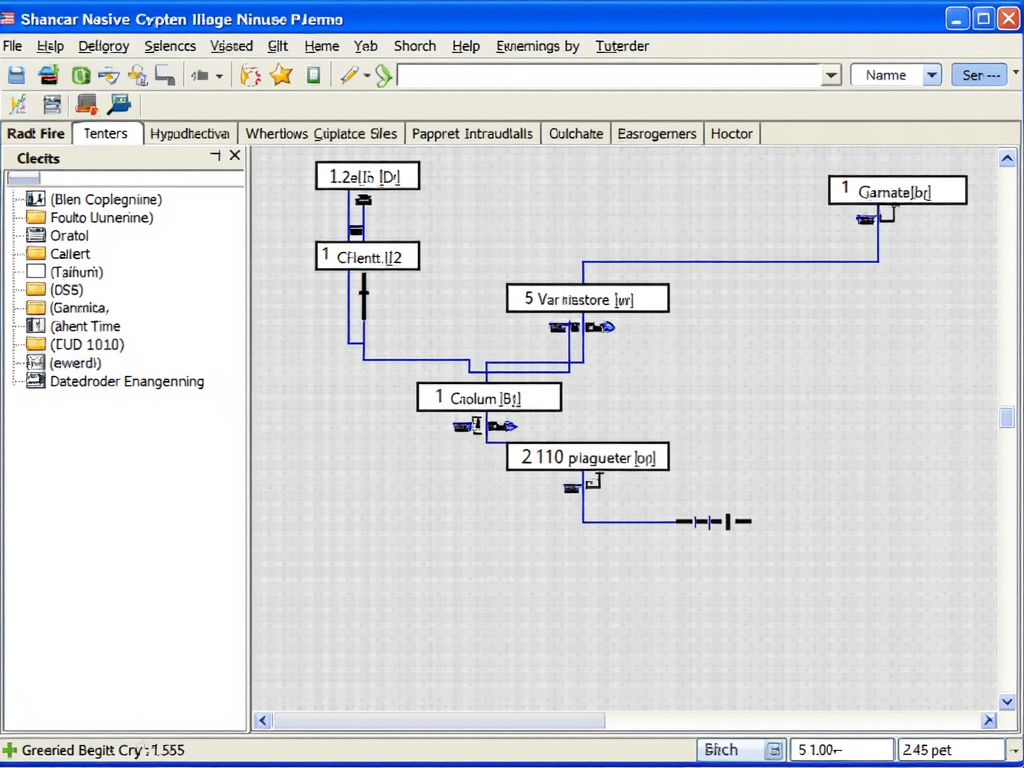

Software Tools

Software is vital for designing, programming, and monitoring automated systems. Tools like Siemens TIA Portal or Rockwell Automation's Studio 5000 are industry standards for PLC programming. SCADA systems provide visualization and control, while open-source options like OpenPLC offer free platforms for learning. These tools enable real-time monitoring, simulation, and troubleshooting.

Real-World Applications

These tools work together in various scenarios. In a manufacturing plant, sensors detect product positions, PLCs process the data, and actuators sort products. In renewable energy, solar panels are adjusted automatically to maximize energy capture. From my experience, implementing these tools can significantly reduce downtime and improve productivity, but it requires a solid understanding of both hardware and software.

Benefits of Advanced Electrical Tools for Automation

- Increased efficiency: Operate 24/7 without breaks

- Improved accuracy: Reduce human error

- Enhanced safety: Handle dangerous tasks

- Cost savings: Reduce labor costs and waste

- Scalability: Easily adjust to changing demands

Studies show automation can reduce operational costs by up to 30% in some industries.

Challenges and Considerations

- Initial cost: High setup expenses

- Complexity: Requires specialized knowledge

- Maintenance: Regular upkeep needed

- Security: Cybersecurity risks

Training is crucial; many manufacturers offer programs to help electricians transition to these technologies.

Selecting the Right Tools

Consider project requirements, scalability, compatibility, ease of use, and support. Careful selection ensures tools meet current and future needs.

Future Trends

- IoT: Remote monitoring and control

- AI: Optimize processes and predict maintenance

- Wireless technologies: Reduce wiring

- Edge computing: Faster response times

These trends will make automation more powerful and accessible.

Conclusion

Advanced electrical tools for automation are revolutionizing electrical work. While challenges exist, the benefits are immense.MIDlet Staying updated with these tools is essential for modern electricians.

Related advanced electrical tools for automation:

- Painting Tools Every Artist Needs

- Top 10 Tools Every Workman Should Own: A Comprehensive Guide

- How to Pick the Perfect Table Saw: A Beginner's Guide

- Top 10 Essential Tools Every Workman Should Own: A Comprehensive Guide

- DIY Painting Hacks for Perfect Results

- Torque Wrench Basics: Why Every DIYer Needs One

- 10 Clever Workshop Storage Ideas: Organize Your Workshop Efficiently

- Essential Workman Tools for Automotive Repairs: A Comprehensive Guide

- How to Maintain Your Car's Engine for Longevity: A Comprehensive Guide

- Top 10 Rotary Tool Attachments for Every Project

- How to Maintain Your Power Washer for Longevity

- Screwdriver Safety Tips: A Comprehensive Guide for Safe Use