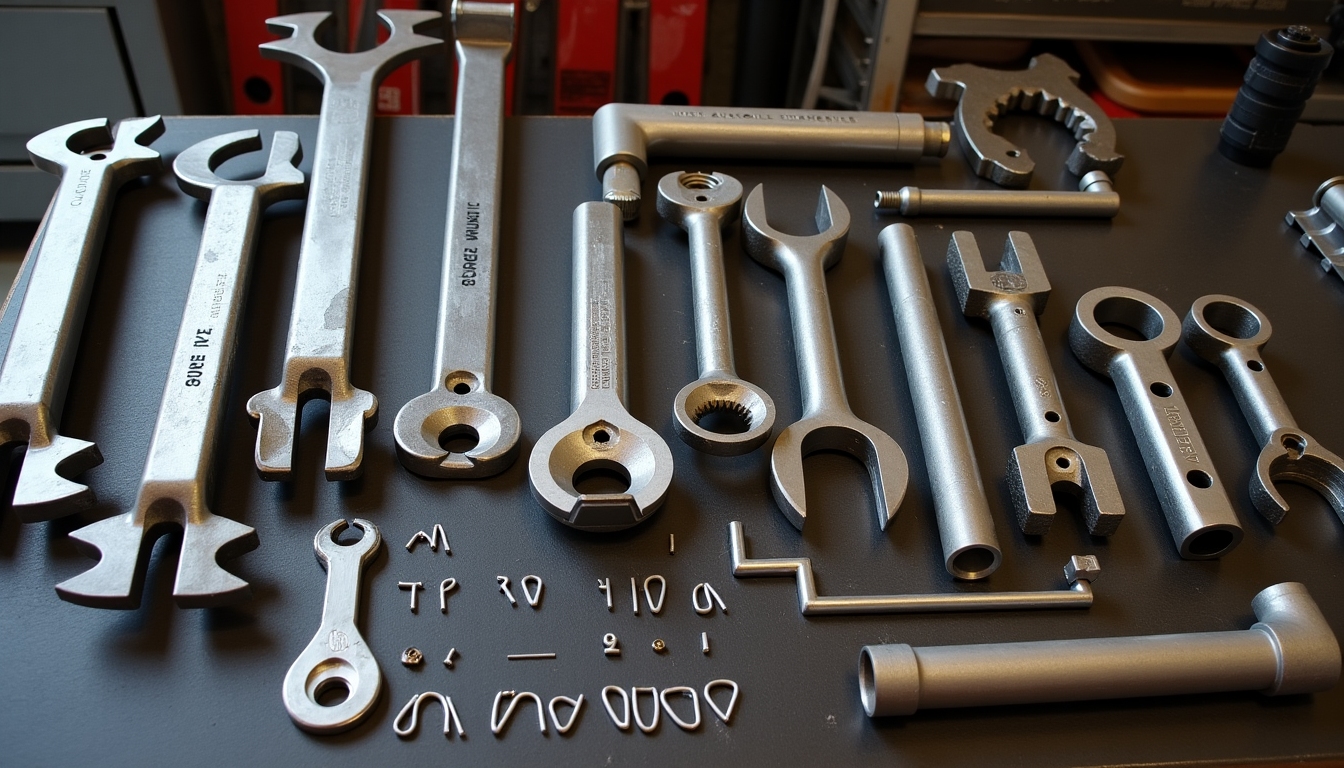

Discovering the Essential Workman Tools for Metalworking

Metalworking is an ancient craft that has evolved with time, requiring precision and skill. Workman tools for metalworking play a crucial role in shaping and creating intricate designs in metal. Whether you're a seasoned craftsman or a beginner, having the right hand tools can make a significant difference in the quality of your work.

The Importance of Choosing the Right Workman Tools

Selecting the appropriate tools can significantly influence the outcome of your metalworking projects. Workman tools for metalworking are designed to provide the necessary leverage and precision. From cutting and shaping to finishing and detailing, each tool has a specific function. Ensuring you have a well-rounded toolkit is key to achieving professional-grade results.

Essential Hand Tools for Every Metalworker

Here's a list of must-have hand tools that should be in every metalworker's arsenal:

- Ball-peen Hammer: Ideal for striking punches and shaping metal edges.

- Measuring Tape: Accurate measurements ensure precision in cuts and assemblies.

- Pliers and Vices: Essential for gripping, bending, and holding metal pieces securely.

- Files: Used for smoothing rough edges and surface finishing.

- Drill: Vital for creating holes, always choose one with adjustable speeds for various materials.

These tools not only aid in craftsmanship but also enhance your safety by offering better control and efficiency.

Personal Insights on Using Workman Tools

Having worked in metal fabrication for over a decade, I've come to appreciate the simplicity and effectiveness of well-made tools. The first time I used a ball-peen hammer was a revelation. The control and precision it offered transformed a simple sheet of metal into a detailed ornamental design. Investing in high-quality tools has also reduced the frequency of injuries and mistakes in my projects.

Maintaining Your Metalworking Tools

Proper maintenance is crucial for the longevity and performance of your tools. Here's how to keep them in the best shape:

- Regular Cleaning: Remove any metal shavings and dust after each use.

- Lubrication: Apply a light oil to moving parts to prevent rust and ensure smooth operations.

- Sharpening and Calibration: Tools like drills and saw blades need to be sharp and well-calibrated for optimal performance.

Tools that Stand the Test of Time

Among the best experiences in metalworking is witnessing tools that have been passed down through generations. My grandfather's old vices and calipers still function impeccably today. This longevity underscores the value of investing in robust, quality workman tools for metalworking that are designed to withstand the rigors of daily use.

Conclusion: Investing in Quality

Investing in quality workman tools for metalworking is not just about ease of use and efficiency but also about ensuring the safety and longevity of your craft. As you hone your skills, remember that the right hand tools can greatly enhance your ability to create detailed and precise metalwork.

Related workman tools for metalworking:

- Essential Tips for Tool Maintenance: A Comprehensive Guide

- Best Wrench Sets for Construction Workers: A Comprehensive Guide

- The Essential Guide to Workman Tools for Plumbing

- Exploring Advanced Electrical Tools for Automation

- Top 10 Tools Every Workman Should Own

- Mastering Automotive Repairs with Workman Tools

- Essential Screwdriver Safety Tips for Every Task

- Must-Have Hand Tools for Mechanics

- Guide to Ergonomic Tool Belts

- Must-Have Workman Tools for Every Toolbox

- The Ultimate Guide to Rotary Tool Accessories and Attachments

- Comprehensive Guide to Power Tools for Woodworking Enthusiasts