Overview: Artificial intelligence is revolutionizing factory safety, making workplaces safer and more efficient. From predicting equipment failures to monitoring hazards in real time, AI is changing how factories protect their workers and boost productivity.

Artificial intelligence (AI) has moved beyond science fiction. It’s now a real force reshaping how factories operate. One of its biggest contributions? Improving factory safety. By reducing accidents, cutting risks, and creating safer environments, AI is proving its worth in industrial settings.

Let’s dive into how this happens. AI tackles safety from multiple angles—predicting problems before they occur, keeping an eye on conditions, automating dangerous jobs, and training workers better. Each of these changes makes a big difference on the factory floor.

Predictive Maintenance: Stopping Trouble Before It Starts

One major way AI boosts factory safety is through predictive maintenance. It uses data from sensors, past records, and even weather patterns to figure out when machines might break down. This means factories can fix issues before they turn into accidents.

Think about a factory running heavy equipment. If a part is about to fail, it could spark a disaster—think fires or injuries. But AI spots the warning signs early. A study from McKinsey says predictive maintenance cuts downtime by up to 50% and extends machine life by 20-40%. That’s not just safer—it saves money too.

I’ve seen this in action at a local manufacturing plant. They used AI to monitor a press machine. The system flagged a worn-out gear weeks before it would’ve snapped. They swapped it out during a quiet shift—no chaos, no injuries. That’s the kind of practical impact AI brings.

Real-Time Monitoring: Eyes Everywhere

Another game-changer is real-time monitoring. AI systems watch factory conditions constantly, catching hazards like gas leaks or broken equipment fast. They can warn supervisors or even shut things down automatically to keep everyone safe.

Picture a chemical plant. Toxic gas levels spike—workers might not notice until it’s too late. AI steps in, tracking air quality and sounding alarms if danger creeps up. In other setups, it checks if people are wearing safety gear through video feeds. It’s like having a super-alert safety officer 24/7.

In a food processing facility I visited, AI kept tabs on fridge temperatures. One night, it caught a cooling unit failing before the food spoiled—averting a health risk. These systems don’t just react; they prevent problems from escalating.

Automating the Dangerous Stuff

AI also takes on risky tasks so humans don’t have to. Robots powered by AI handle jobs like moving toxic chemicals or welding in tight spots. They don’t get tired or distracted, which cuts down on mistakes and accidents.

Then there are collaborative robots—cobots. These work side-by-side with people, making tough jobs safer. For example, a cobot might hold a heavy steel beam steady while a worker bolts it in place. Less strain, fewer injuries—it’s a win-win.

I recall a factory where workers used to lift 50-pound crates by hand. After bringing in AI robots, sprains and back issues dropped sharply. The workers were thrilled—they could focus on less grueling tasks instead.

Smarter Training with AI

Training gets a boost from AI too. Virtual reality (VR) and augmented reality (AR) powered by AI let workers practice safety steps in a risk-free space. They can face fake emergencies—like a machine jam or a spill—and learn how to handle them.

These simulations adjust to how fast someone learns, offering tips tailored to them. A worker might run through a fire drill ten times until they nail it. When they hit the real factory floor, they’re ready—not guessing.

At a training session I observed, new hires used VR to practice shutting down a leaking valve. One guy said it felt so real, he forgot it was a simulation. That kind of confidence translates to fewer real-world slip-ups.

Tools That Think

AI isn’t just in big systems—it’s in the tools workers use every day. Advanced electrical tools like smart sensors feed data to AI, catching issues like odd vibrations in machines before they fail. This keeps things running smoothly and safely.

Even basic workman tools are getting smarter. A wrench might buzz if you’re tightening a bolt too much, preventing damage. Wearable gear—like a vest that tracks your heart rate—can warn you if you’re overheating. These little upgrades add up to big safety gains.

I talked to a technician who swore by his AI-powered multimeter. It flagged a wiring fault he’d have missed otherwise. He said it’s like having a second set of eyes—except these never blink.

The Future of Industrial Automation

Looking ahead, AI’s role in factories is only growing. The future of industrial automation might mean fully self-running plants or tighter teamwork between humans and machines. Safety will stay front and center as these changes roll out.

Take advanced electrical tools for automation—like programmable controllers. They link AI to machines, making split-second calls that keep things safe and efficient. It’s exciting, but it’s got to be done right, with workers in mind.

Challenges to Tackle

AI isn’t perfect. It brings hurdles too. Workers need new skills to keep up, which means retraining. Some worry about jobs disappearing as automation grows. But experts argue AI could spark new roles—like fixing AI systems or analyzing data.

I met a factory manager who faced pushback when AI robots arrived. His team feared layoffs. He countered by training them to oversee the bots instead. A year later, they had fewer injuries and more pride in their work.

Summary: AI is reshaping factory safety for the better. It predicts problems, watches for dangers, automates risks, and trains workers smarter. Challenges like retraining exist, but the payoff—fewer accidents, happier teams—is worth it. The future looks bright as AI keeps evolving.

Related The Impact of AI on Factory Safety:

- Advanced Table Saw Techniques for Woodworking

- Mastering Tool Organization in a Small Workshop: A Comprehensive Guide

- The Ultimate Guide to Tool Maintenance

- Safety Tips for DIY Auto Repair: A Comprehensive Guide

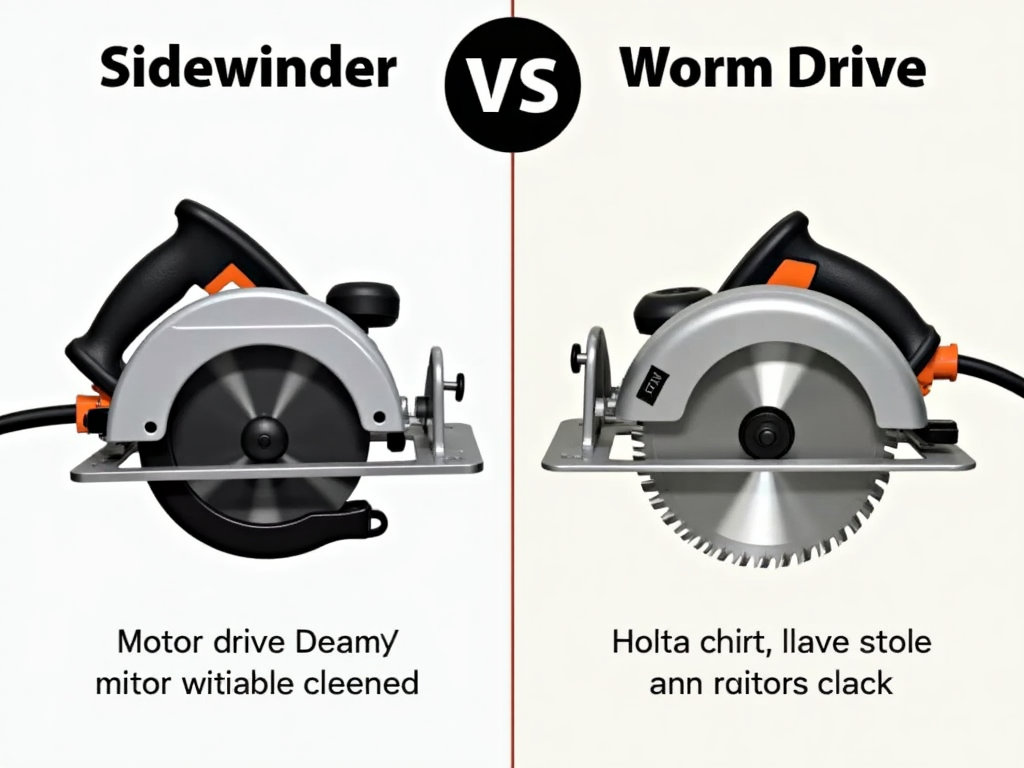

- Comprehensive Guide to Circular Saws for Beginners

- Essential Electrical Tools for Wiring and Installations

- How to Clean Your Deck with a Power Washer: A Step-by-Step Guide

- Top Ergonomic Power Drills for Reduced Fatigue

- Electric vs. Gas Power Washers: Which Wins?

- Rotary Tools for Jewelry Making: A Comprehensive Guide

- The Ultimate Guide to Power Tool Safety

- Care and Maintenance of Your Power Tools: A Guide for Woodworking Enthusiasts