Your tools are the backbone of your work as a mechanic. Keeping them in great shape ensures they last longer and perform better. In this guide, we’ll explore tool maintenance tips for mechanics with simple, actionable steps. Whether you’re new to the trade or a seasoned pro, these tips will help you maintain your workman tools effectively.

Cleaning and Storing Your Tools

Cleaning your tools after every job is a must. Grease and dirt can wear them down over time. Use a rag to wipe off grime, or soak them in soapy water for tougher messes. Dry them completely to stop rust from forming.

Storage matters too. A sturdy toolbox keeps everything safe and organized. Add foam inserts to stop tools from banging into each other. If your garage is damp, toss in some silica gel packs to soak up moisture.

I once skipped cleaning my tools after a long day. A few weeks later, I found rust on my favorite wrench. It was a lesson learned the hard way. Now, I wipe down every tool before putting it away, no matter how tired I am. It’s saved me money and frustration.

Sharpening and Calibrating Tools

Dull tools make your work harder and less safe. Tools like drill bits and chisels need regular sharpening. A sharpening stone is a small investment that pays off big. For tools like calipers, calibration keeps them accurate.

Here’s how to sharpen a chisel: - Clamp it steady. - Use a sharpening stone at a 25-30 degree angle. - Slide the stone along the edge until it’s sharp. - Finish with a finer stone for a smooth edge.

Sharpening my first chisel was intimidating. I worried I’d ruin it. But after a few tries, I got the hang of it. Now, I enjoy the process—it’s a quiet break from the noise of the garage. Sharp tools make every job easier.

Inspecting and Replacing Tools

Check your tools often for wear. Look for cracks or dull edges on screwdrivers and wrenches. For power tools, inspect cords for damage. If something’s too worn to fix, replace it. A broken tool can mess up your work or hurt you.

When buying replacements, go for quality. Cheap tools wear out fast. Brands like Craftsman or Snap-on are worth the extra cost for durability.

I had an old wrench I couldn’t let go of. One day, it slipped and I smashed my hand. After that, I started checking my tools regularly. Replacing that wrench was tough, but it taught me to prioritize safety over sentiment.

Essential Screwdrivers for Mechanics

Screwdrivers are a mechanic’s best friend. Having the right ones saves time and effort. Here’s a list of essential screwdrivers for mechanics:

| Type | Use |

|---|---|

| Flathead | Single-slot screws, prying |

| Phillips | Cross-slot screws, better grip |

| Torx | Star-shaped screws, automotive use |

| Precision Set | Tiny screws in small parts |

Keep them clean and store them so the tips don’t get damaged. A worn tip can strip screws, so replace them when needed.

My go-to Phillips screwdriver has been with me for years. It fits my hand perfectly, and I’ve kept its tip sharp with proper care. Once, I used it to fix a tricky engine part when no other tool would do. It’s proof that good workman tools make a difference.

Why Maintenance Matters

Taking care of your tools isn’t just about saving money. It’s about doing better work. Clean, sharp tools get the job done faster. Well-stored tools are ready when you need them. Over the years, I’ve seen mechanics struggle with neglected gear—it’s a hassle you can avoid.

The U.S. Bureau of Labor Statistics notes that mechanics rely heavily on their tools daily (bls.gov). Keeping them in top shape is part of the job.

Final Thoughts

Tool maintenance tips for mechanics boil down to this: clean, store, sharpen, and inspect. Add in quality screwdrivers and you’re set. Your tools are an investment—treat them right, and they’ll serve you well for years. Small habits like these turn good mechanics into great ones.

Related Tool Maintenance Tips for Mechanics:

- How to Organize Your Tool Collection for Maximum Efficiency

- Safety First: Essential Gear for Workman Tool Users

- Mastering Complex Projects: A Guide to Advanced Workman Tools

- The Future of Woodworking Tools: Safety and Innovation

- 5 Common Mistakes with Power Tools and How to Avoid Them

- Best Cordless Drills for Every Budget: A Comprehensive Guide

- The Ultimate Guide to Specialized Workman Tools for Metalwork

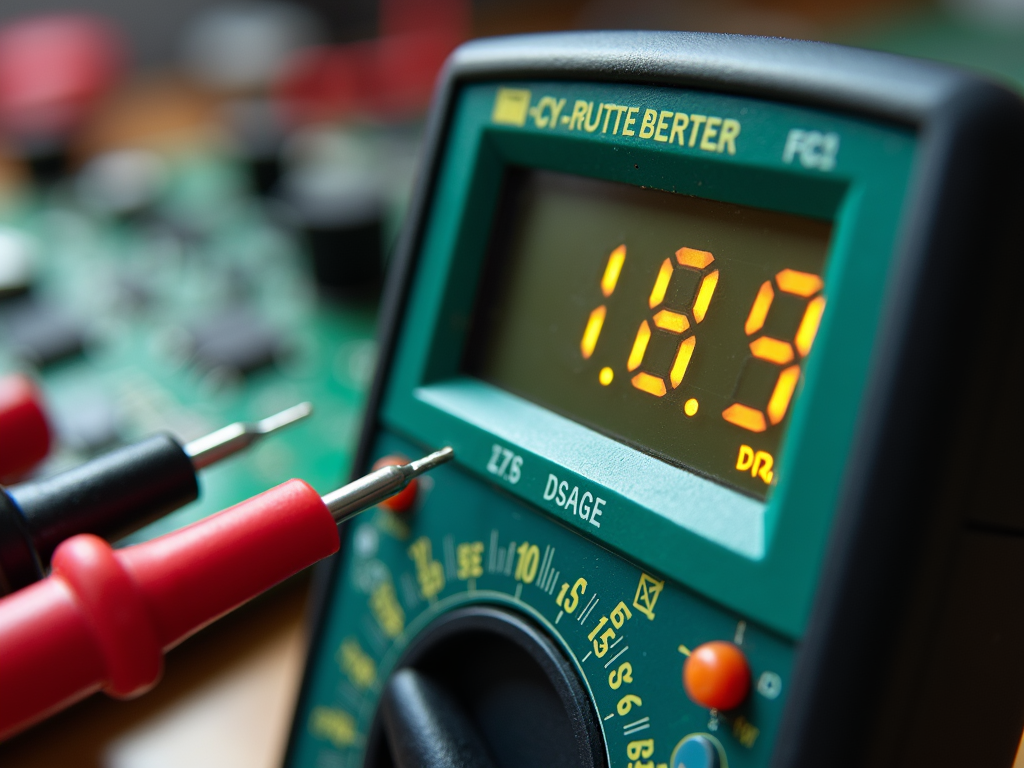

- Choosing the Right Multimeter for Your Needs: A Comprehensive Guide

- Organizing Your Toolbox: Tips and Tricks for Every Handyman

- The Importance of Quality Tools in DIY Projects

- Essential Chisels in a Woodworker’s Toolkit: Your Guide to the Best Tools

- Essential Safety Tips for Your Home Workshop