Proper tool maintenance is crucial for both the longevity of your tools and your safety. In this guide, we'll explore essential tips for maintaining your tools, with a focus on screwdrivers and other common workman tools.

Cleaning Your Tools

Keeping your tools clean is the first step in maintenance. Dirt, grease, and debris can cause rust and damage over time. Here's how to clean different types of tools:

- Hand tools like screwdrivers and wrenches: Wipe them down with a dry cloth after each use. For stubborn dirt, use a mild soap and water solution, then dry thoroughly.

- Power tools: Follow the manufacturer's instructions for cleaning. Generally, you can use a brush to remove dust and debris, and a damp cloth for the exterior.

Remember, never immerse electrical tools in water.

Cleaning your tools isn't just about aesthetics; it's about preventing damage and ensuring they function properly. For hand tools like screwdrivers, a simple wipe with a dry cloth can suffice for everyday use. However, if you've been working with adhesives or other sticky substances, you might need to use a mild solvent to remove residue. Be sure to dry the tool completely afterward to prevent rust.

For tools with moving parts, like pliers or adjustable wrenches, make sure to clean between the joints. A small brush can help remove debris from these areas.

If you notice rust on your tools, don't panic. Light rust can often be removed with a wire brush or fine-grit sandpaper. For more severe cases, you might need to use a rust remover product. After removing the rust, apply a thin layer of oil to protect the metal.

Essential Maintenance Tasks

- Clean tools after each use

- Store tools in a dry place

- Regularly inspect tools for damage

- Sharpen blades and tips as needed

- Lubricate moving parts

Storing Your Tools Properly

Proper storage is key to preventing damage and ensuring your tools are ready when you need them. Here are some tips:

- Keep tools in a dry place: Moisture can lead to rust. Consider using a dehumidifier in your workshop if necessary.

- Organize your tools: Use toolboxes, pegboards, or tool belts to keep everything in its place. This not only protects your tools but also makes them easier to find.

- Store tools with care: For example, hang hammers and screwdrivers to prevent them from getting damaged in a pile.

Proper storage is about more than just keeping your tools organized; it's about protecting them from the elements and accidental damage. A toolbox is a classic choice, offering portability and protection. Look for one with compartments to keep small items like screws and nails separate from larger tools.

Pegboards are excellent for workshops, allowing you to see all your tools at a glance and access them easily. However, they don't offer much protection from dust or moisture, so they're best used in a controlled environment.

Tool belts are great for keeping essential tools on hand during a project, but they shouldn't be used for long-term storage. Tools left in a belt can get damaged or cause injury if you forget they're there.

Regardless of the storage method, make sure your tools are dry before putting them away. Moisture can lead to rust, especially in metal tools.

Storage Solutions Comparison

| Storage Type | Portability | Organization | Protection |

|---|---|---|---|

| Toolbox | High | Good | Excellent |

| Pegboard | Low | Excellent | Good |

| Tool Belt | High | Fair | Fair |

Inspecting Your Tools Regularly

Regular inspections can catch potential issues before they become serious problems. Here's what to look for:

- Wear and tear: Check for cracks, bends, or other signs of damage.

- Loose parts: Make sure handles are secure and moving parts are functioning properly.

- Sharpness: For tools like chisels or planes, ensure the blades are sharp and free of nicks.

Regular inspections are your first line of defense against tool-related accidents. Set a schedule to check your tools, perhaps at the beginning of each season or before starting a big project.

When inspecting hand tools, look for: - Cracks or splits in handles - Bent or warped metal parts - Loose or wobbly components - Signs of rust or corrosion

For power tools, check: - The power cord for frays or exposed wires - The plug for damage - The tool's housing for cracks - The trigger or switch for proper function

If you find any issues, don't hesitate to repair or replace the tool. It's better to be safe than sorry.

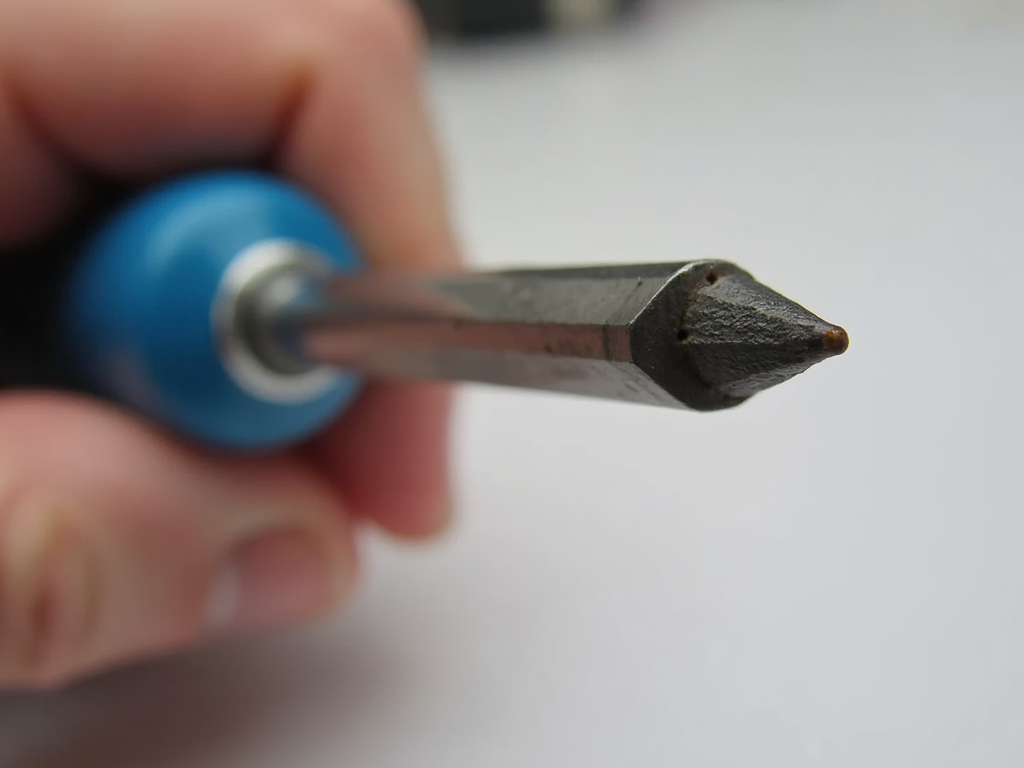

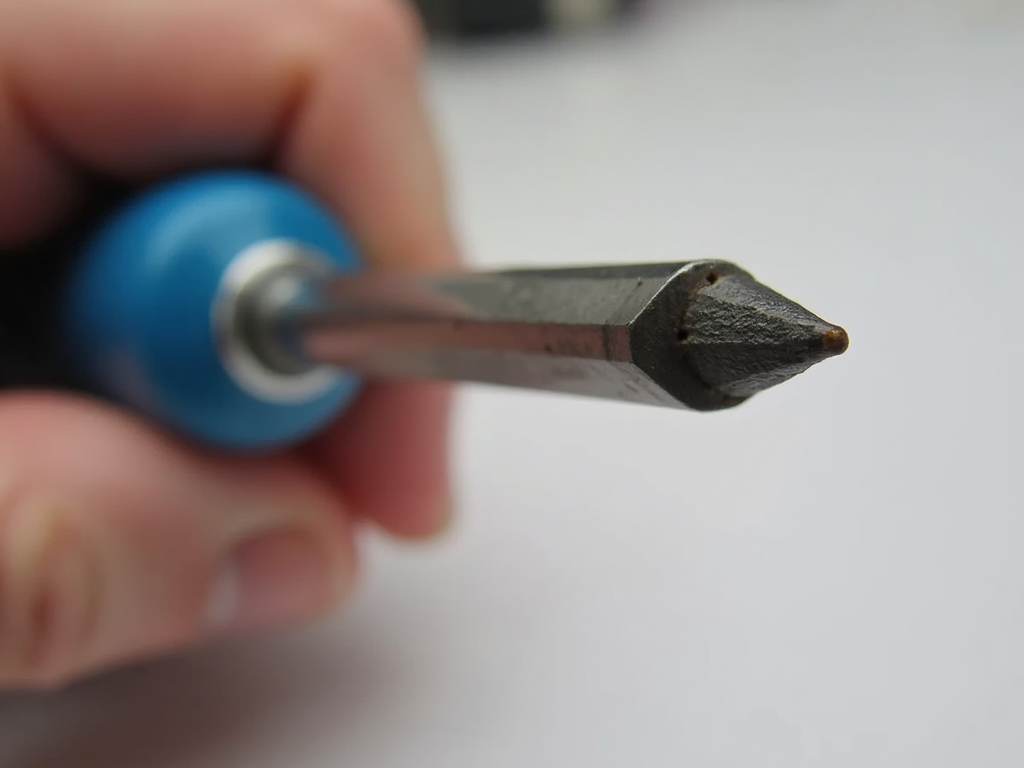

Screwdriver Safety Tips

Screwdrivers are common tools, but they can be dangerous if not used properly. Here are some safety tips:

- Use the right size: Using a screwdriver that's too small or too large for the screw can lead to slipping and injury.

- Don't use as a pry bar: Screwdrivers are not designed for prying and can break or cause injury.

- Keep the tip in good condition: A worn tip can slip, so replace or sharpen it as needed.

- Hold the handle firmly: Ensure a good grip to prevent the tool from slipping out of your hand.

Screwdrivers might seem harmless, but they can cause serious injuries if misused. Here are some additional tips:

- Use the correct type: Flathead and Phillips screwdrivers are not interchangeable. Using the wrong type can damage the screw and the tool.

- Apply steady pressure: Pushing too hard can cause the screwdriver to slip, while not pushing hard enough can strip the screw.

- Keep your free hand clear: Don't hold the object you're screwing into with your other hand, in case the screwdriver slips.

- Avoid electrical work: Unless you're using an insulated screwdriver designed for electrical work, never use a screwdriver near live wires.

Maintaining Power Tools

Power tools require special care due to their electrical components. Here are some tips:

- Unplug before maintenance: Always disconnect the power source before cleaning or inspecting.

- Check cords and plugs: Look for fraying or damage, and replace if necessary.

- Lubricate moving parts: Use the recommended lubricant for your tool.

- Store properly: Keep power tools in their cases or on shelves, away from moisture.

General Tool Safety Tips

While specific tools have their own safety considerations, there are some universal precautions you should take:

- Wear appropriate protective gear: This might include safety glasses, gloves, or ear protection, depending on the tool and task.

- Keep your workspace tidy: A cluttered area can lead to accidents. Keep your tools organized and put them away when not in use.

- Use tools for their intended purpose: Don't try to make a tool do something it's not designed for. This can damage the tool and put you at risk.

- Stay focused: Avoid distractions while using tools. A moment of inattention can lead to injury.

A Personal Experience

I once had a favorite screwdriver that I used for years. By keeping it clean and storing it properly, it lasted much longer than expected. One day, during a routine inspection, I noticed the handle was cracked. If I hadn't caught it, it could have broken during use, potentially causing an injury. This experience taught me the importance of regular maintenance and inspection.

Creating a Tool Maintenance Routine

To make maintenance a habit, consider setting up a routine. Here's a simple schedule you can follow:

- After each use: Clean tools and store them properly.

- Weekly: Inspect frequently used tools for any signs of wear.

- Monthly: Perform a more thorough inspection of all tools, including those used less often.

- Annually: Deep clean your tools and consider professional servicing for power tools if needed.

By sticking to a schedule, you'll ensure your tools are always in top condition.

Conclusion

By following these tool maintenance tips, you'll not only extend the life of your tools but also ensure a safer working environment. Remember, a little care goes a long way in preventing accidents and saving money on replacements. Make maintenance a habit, and your tools will serve you well for years to come.

Related Tool Maintenance Tips for Longevity and Safety:

- Understanding the Importance of Advanced Safety Features in Power Tools

- Essential Tools for Every Handyman: A Comprehensive Guide

- The Future of Workshop Equipment: Trends to Watch

- How to Pick the Perfect Screwdriver for Any Task

- A Simple Guide to Your Home’s Electrical Setup

- DIY Projects for Beginners: Getting Started with Basic Tools

- Safety First: Protecting Yourself in the Metalworking Shop

- Breaking It Down

- Ultimate Guide to Mobile Storage Carts for Tools

- Tool Maintenance: Tips for Longevity

- The History of Black & Decker: Pioneers of Power Tools

- The Benefits of Using a Rotary Tool: A Must-Have for Every Craftsman