Torque specifications are key to mechanical work, ensuring bolts and nuts are tightened just right. This guide dives into what they are, why they’re important, and how to use them properly—perfect for pros and DIYers alike.

What Are Torque Specifications?

Torque specifications tell you how tight to make a fastener, like a bolt or nut, in things like cars or machines. Manufacturers set these levels to keep everything safe and working well. Understanding Torque Specifications isn’t just for experts—it’s a must-know for anyone turning a wrench. With over 10 years as a mechanic, I’ve learned that getting torque right can save you headaches down the road.

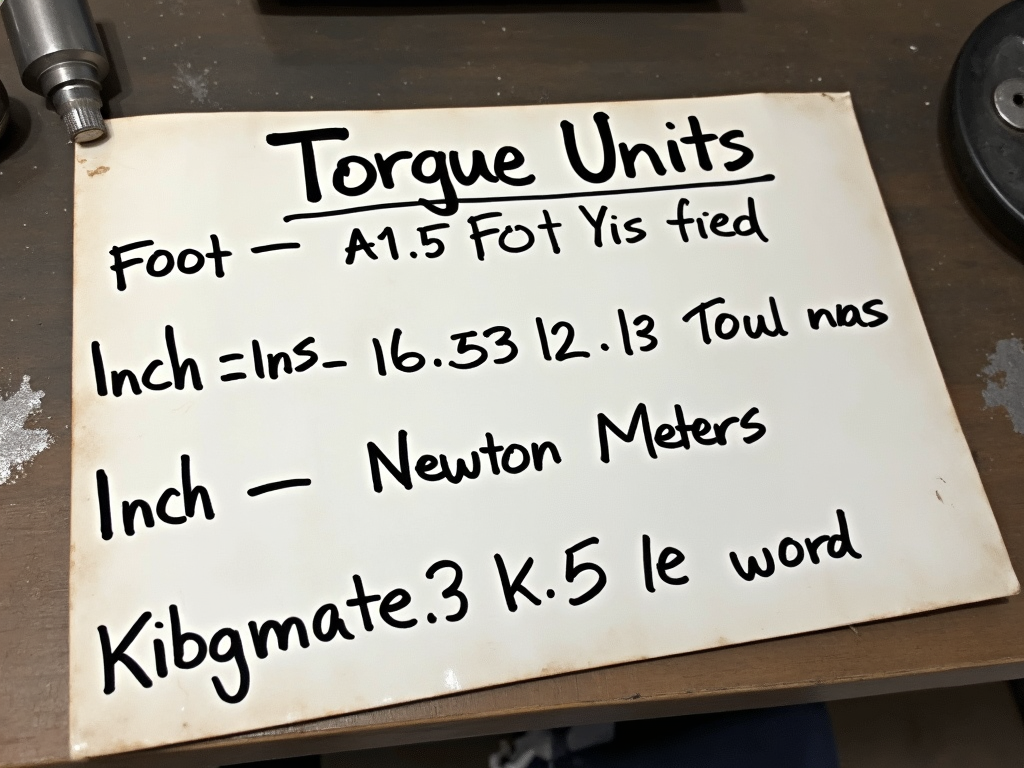

Think of torque as a measure of twisting force. It’s usually shown in units like foot-pounds (ft-lb) or Newton-meters (Nm). Every job has its own spec, and sticking to it is what separates a solid fix from a risky one.

Why Torque Specifications Matter

Getting torque right keeps things together—literally. Too loose, and parts can rattle apart. Too tight, and you might break something. I’ve seen loose bolts cause a wheel to wobble and overtightened ones snap off in an engine. Safety’s on the line too—imagine a car part failing because the torque was off.

Correct torque also protects your work. It stops threads from stripping and keeps pieces from warping. Whether you’re fixing a bike or a truck, Understanding Torque: Essentials for Every Mechanic starts with knowing why these specs exist.

How to Read Torque Specifications

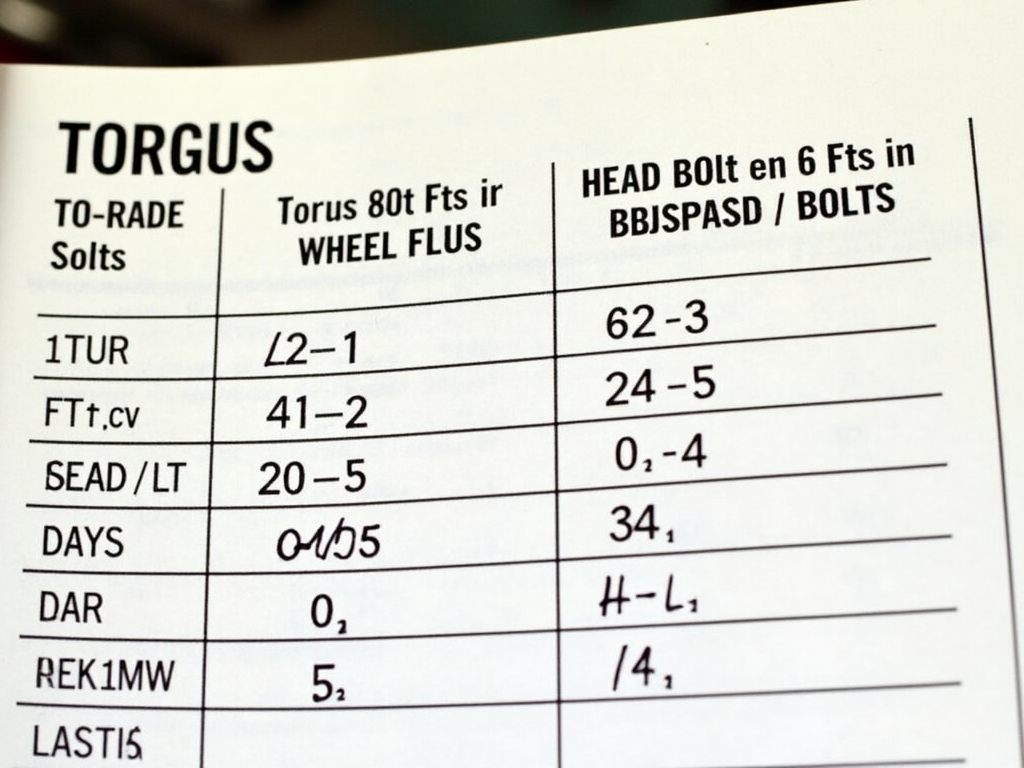

Torque specs look simple but pack a lot of info. They’re written as a number and unit—like 25 ft-lb or 34 Nm. Sometimes they add extras, like ‘dry’ (no oil) or a tightening order for multiple bolts. Here’s a quick table to help:

| Unit | Abbreviation | Conversion to ft-lb |

|---|---|---|

| Foot-pound | ft-lb | 1 |

| Inch-pound | in-lb | 0.0833 |

| Newton-meter | Nm | 0.7376 |

| Kilogram-meter | kg-m | 7.233 |

Check the manual for your project—it’ll list the exact spec. If it says 50 Nm with lubricant, use oil and match that number. It’s straightforward once you get the hang of it.

Common Mistakes to Avoid

Overtightening is a big one. I messed up once on a car engine—cranked a bolt too hard and stripped the threads. It was a pricey lesson. Use a torque wrench every time; guessing doesn’t cut it. Another slip-up is mixing units. If the spec says ft-lb and your wrench is on Nm, you’ll miss the mark. Double-check before you start.

Skipping the tightening sequence can also mess things up. If a manual says to tighten bolts in a star pattern, do it—otherwise, pressure won’t spread evenly. Little things like this make a difference.

Tools You’ll Need

A torque wrench is your main tool here. There are a few types: - Beam-type: Cheap and basic, but you have to watch the scale yourself. - Click-type: Clicks when you hit the right torque—my go-to for most jobs. - Digital: Super accurate with a readout, though pricier.

Essential wrenches for automotive repair include these, plus socket wrenches and adjustable ones for other tasks.

You’ll also want workman tools like extensions and sockets. I keep a solid click-type wrench in my kit—it’s reliable and easy. Pick tools you trust, and keep them clean.

Best Practices for Applying Torque

Start clean—dirty threads can throw off torque. If the spec calls for oil, use it; if not, keep it dry. Tighten in the right order—check the manual for patterns like crisscross or star. Hold the wrench by the handle’s middle and pull steady—no jerks.

Test your wrench too. I’ve used ones that were off from wear, so calibrate them if you can. Little steps like these ensure you nail the spec every time.

Wrapping It Up

Understanding Torque Specifications is a game-changer for mechanical work. It’s about safety, durability, and doing the job right. Use a torque wrench, follow the specs, and avoid shortcuts—you’ll save time and trouble. This guide’s got you covered for your next project.

Related Understanding Torque Specifications:

- Understanding Torque: Essentials for Every Mechanic

- Top 10 Essential Tools for Every DIY Enthusiast

- Essential Wrenches for Automotive Repair: A Mechanic’s Guide

- Choosing the Right Drill Bits for Electrical Installations: A Comprehensive Guide

- The Beginner's Guide to Essential Workman Tools

- Staying Safe with Hand Tools

- Understanding Multimeters: Features and Usage

- How to Choose the Right Electrical Tools for Your Project

- DIY Projects You Can Tackle with Basic Hand Tools

- Beginner’s Guide to Fixing Common Plumbing Issues

- Top 10 Must-Have Tools for DIY Beginners

- Advanced Woodworking Techniques for Enthusiasts