Proper maintenance of metalworking tools is essential for both safety and performance. Regular care not only extends the life of your tools but also ensures a safer working environment. In this article, we'll explore practical tips for maintaining your tools, advanced safety techniques for experienced metalworkers, and common mistakes to avoid.

Cleaning Your Tools

Keeping your metalworking tools clean is the first step in maintenance. Debris and residue can cause tools to malfunction or become unsafe. Here's how to clean different types of tools:

- Hand Tools: Use a wire brush to remove rust and a soft cloth for polishing.

- Power Tools: Disconnect from power, then use compressed air to blow out dust and a damp cloth for wiping down.

Lubrication and Protection

Lubrication prevents wear and tear. Use the right lubricant for each tool:

- Cutting Tools: Apply cutting oil to reduce friction.

- Moving Parts: Use machine oil for smooth operation.

Apply lubricants sparingly to avoid attracting dust. According to MIT's tool maintenance guide, using the correct lubricant can significantly reduce wear on cutting tools.

Storage Solutions

Proper storage prevents damage and corrosion. Consider these tips:

- Dry Environment: Store tools in a dry place to prevent rust.

- Tool Chests: Use tool chests with padded drawers to protect tools.

Advanced Safety Techniques

For experienced metalworkers, safety is paramount. Here are some advanced tips:

- Machine Guards: Always use guards on machinery to prevent accidents.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses and gloves.

The OSHA metalworking safety guide emphasizes the importance of machine guards to prevent injuries.

Common Mistakes to Avoid

Avoid these mistakes to ensure safety and tool longevity:

- Neglecting Maintenance: Regular maintenance is key; don't skip it.

- Using Damaged Tools: Inspect tools before use and replace if damaged.

Summary

By following these maintenance practices, you can ensure your metalworking tools remain safe and perform at their best. Remember, a well-maintained tool is a reliable tool. For more information, check out our recommended readings below.

Related Maintaining Your Metalworking Tools for Safety and Performance:

- The Electrician's Guide to Advanced Automation Tools

- Painting Tools Every Artist Needs

- Top 10 Tools Every Workman Should Own: A Comprehensive Guide

- How to Pick the Perfect Table Saw: A Beginner's Guide

- Top 10 Essential Tools Every Workman Should Own: A Comprehensive Guide

- DIY Painting Hacks for Perfect Results

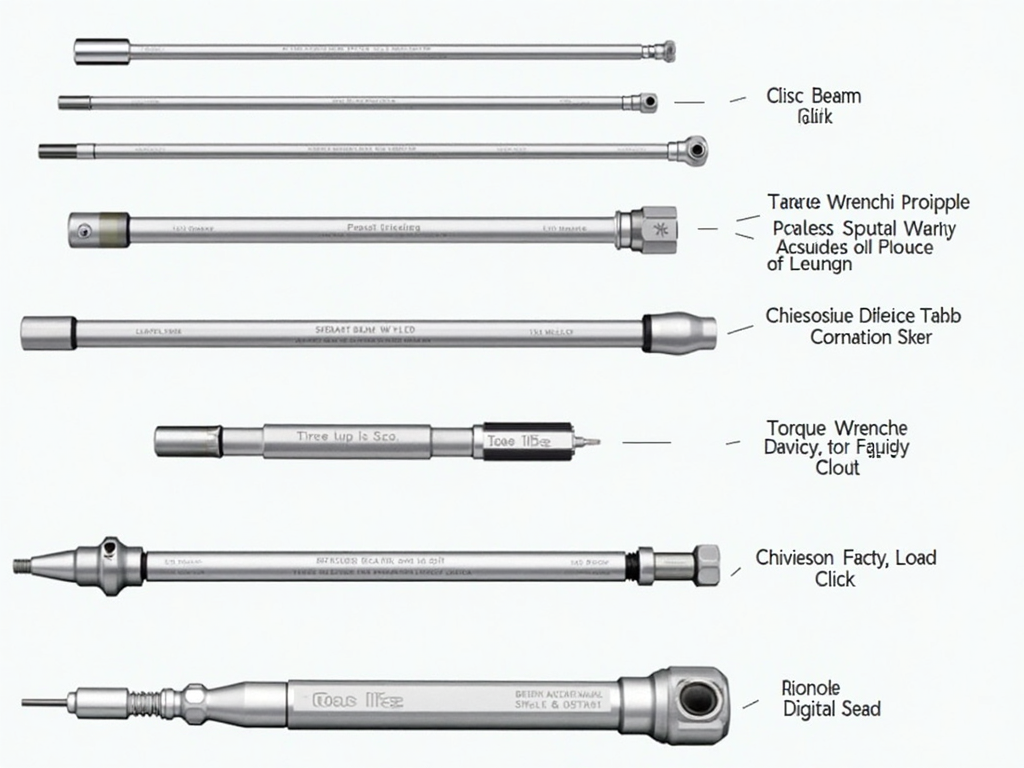

- Torque Wrench Basics: Why Every DIYer Needs One

- 10 Clever Workshop Storage Ideas: Organize Your Workshop Efficiently

- Essential Workman Tools for Automotive Repairs: A Comprehensive Guide

- How to Maintain Your Car's Engine for Longevity: A Comprehensive Guide

- Top 10 Rotary Tool Attachments for Every Project

- How to Maintain Your Power Washer for Longevity