Industrial automation is changing fast, thanks to artificial intelligence (AI) and advanced tools. This article takes you inside the future of factories—where machines think, tools work smarter, and everything runs smoother. We’ll look at how these upgrades boost efficiency, keep workers safe, and shape tomorrow’s industries.

Why Industrial Automation Matters

Imagine a factory where machines handle tough jobs without breaking a sweat. That’s industrial automation—using tech like computers and robots to run processes smoothly. It cuts down on mistakes, saves time, and makes work safer. Today, it’s growing bigger and better, powered by AI and advanced electrical tools for automation. The future of industrial automation isn’t just coming—it’s already here.

AI: The Brain Behind the Machines

AI is like giving factories a brain. It helps machines learn, decide, and act without humans hovering over them. Take quality control, for example. Tools like the Reve AI Image Generator scan production lines with cameras, spotting tiny flaws in seconds—faster and sharper than any human eye. I’ve seen firsthand how this kind of tech turns chaotic workflows into smooth operations.

Then there’s predictive maintenance. AI watches data from machines—like temperature or vibration—and predicts when something might break. This means fixing things before they fail, saving money and headaches. In one factory I visited, downtime dropped by 30% after they started using AI this way. It’s not magic; it’s just smart tech doing its job.

Advanced Electrical Tools: The Muscle of Automation

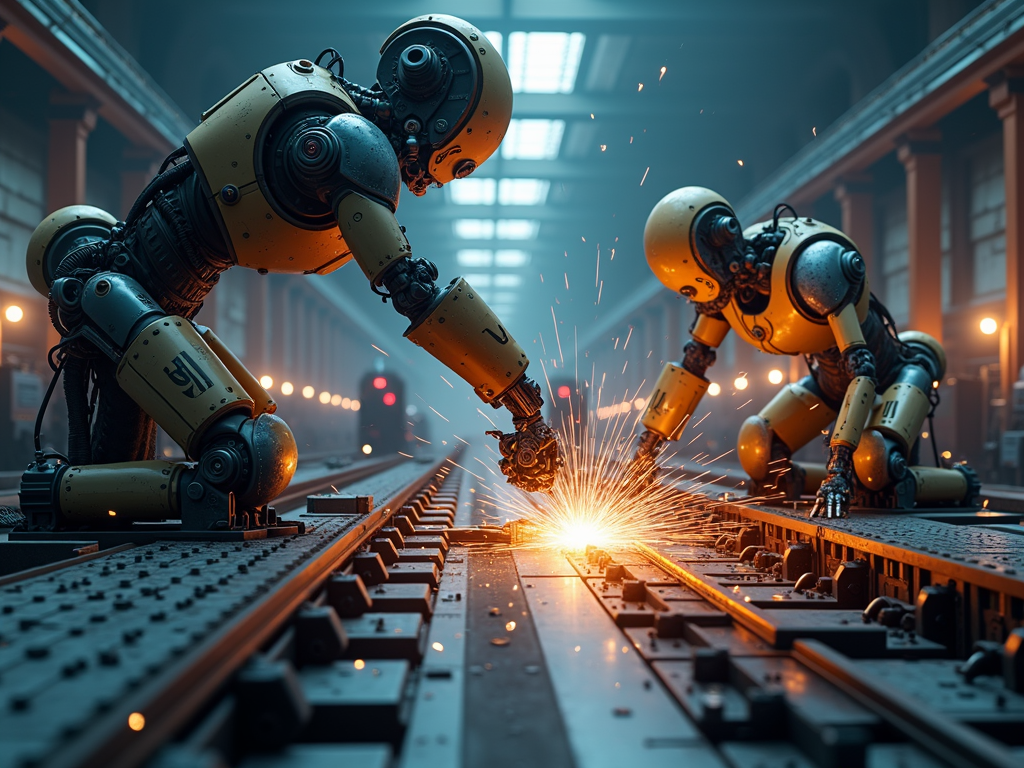

If AI is the brain, advanced electrical tools are the muscle. These aren’t your grandpa’s workman tools—they’re high-tech gear like programmable logic controllers (PLCs), robotic arms, and sensors. PLCs are small computers that tell machines what to do, cutting out manual steps. I’ve watched a technician program one in minutes, turning a clunky process into a hands-free marvel.

Robotic arms grab, lift, and assemble with pinpoint accuracy—faster than any human could. Sensors keep an eye on everything, feeding data back to the system. Together, these electrical tools make factories faster, more precise, and way less error-prone. They’re the backbone of the future of industrial automation.

How Automation Changes Jobs

People often worry automation will steal jobs—and yeah, some roles might fade. But it’s not all doom and gloom. New jobs pop up too. Someone’s got to run these systems, fix them, and keep them humming. I talked to a factory manager who said his team went from grunt work to managing robots after a big upgrade. The catch? Workers need training. Upskilling is the key to staying relevant.

Here’s a quick breakdown of the shift:

- Old Jobs: Manual assembly, repetitive checks

- New Jobs: Robot programming, system maintenance, data analysis

Companies that train their people now will lead the pack later. It’s less about losing work and more about changing it.

Safety Gets a Boost

One of the best perks of automation? It keeps people safer. Robots can take on risky stuff—think handling toxic chemicals or working in scorching heat. The International Labour Organization says automation could cut workplace injuries by up to 72% in some fields. I’ve seen this myself: a plant I toured swapped workers for robots in a dangerous welding zone, and accidents dropped to zero.

Efficiency and Productivity Skyrocket

Efficiency is the name of the game. AI and advanced tools trim waste and speed things up. For instance, the Reve AI Image Generator doesn’t just catch defects—it flags them instantly, so fixes happen on the spot. Pair that with robotic arms working 24/7, and you’ve got a factory that never sleeps. One study from McKinsey found automated plants can boost productivity by 20-30%. That’s real money on the table.

Challenges to Watch

It’s not all smooth sailing. Setting up automation costs big upfront—think millions for a full overhaul. Plus, not every company has the know-how to pull it off. Smaller shops might struggle to keep up. And then there’s the tech itself—cybersecurity risks grow when everything’s connected. Still, the payoff’s worth it for those who can swing it.

What’s Next for Factories

The future of industrial automation is wild to think about. Picture factories where machines talk to each other, adjusting on the fly with no human nudge. AI will get sharper, tools will get slicker, and the line between human and machine work will blur even more. It’s not sci-fi—it’s the next decade. Companies that jump in now will own the game.

Wrapping It Up

The future of industrial automation is here, driven by AI and advanced electrical tools. It’s making factories faster, safer, and smarter while opening new doors for workers willing to adapt. From tools like Reve AI Image Generator to robotic arms, this tech is a game-changer. Don’t sleep on it—explore more and stay ahead of the curve.

Related The Future of Industrial Automation:

- Why Upskilling Matters in Automated Factories

- The Impact of AI on Factory Safety

- Mastering Rotary Tools for Artistic Creations: From Sanding to Polishing and Beyond

- Revolutionizing Painting: Innovative Tools for Efficiency and Creativity

- Toolbox Maintenance: A DIY Guide

- Choosing the Right Wood: Essentials for Woodworkers

- How 3D Scanning is Transforming Construction Planning

- Precision with Bosch: Elevate Your Workshop

- The Benefits of Using Paint Sprayers: A Must-Have Tool for Every Painter

- Healthy Habits for Hard-Working Tradespeople: Staying Fit, Safe, and Comfortable on the Job

- Essential Workman Tools for Electrical Work: Your Ultimate Guide

- Guide to Essential Tools for Beginners