Overview

Want to drill perfect holes every time? This guide dives into mastering the drill press with techniques for better precision, especially in metalworking. From setup to pro tips, we’ll help you sharpen your skills with power tools and achieve top-notch results.

Why the Drill Press Matters

A drill press is more than just a tool—it’s a game-changer for anyone working with metal. Unlike handheld drills, it gives you steady control and pinpoint accuracy. I’ve used one for years, and it’s saved me from countless mistakes. Precision matters because even a tiny error can throw off an entire project.

Power tools for metalworking, like the drill press, are essential for creating clean, consistent holes. Whether you’re building furniture or crafting machine parts, this tool delivers. Let’s explore how to make the most of it.

Setting Up for Success

Good drilling starts with a solid setup. Here’s how I get my drill press ready for precision work:

- Adjust the Table: Move the table to a height where the drill bit clears the workpiece easily. It saves hassle later.

- Clamp It Down: Secure your material with clamps or a vise. I once skipped this step, and my piece spun out of control—lesson learned!

- Pick the Right Bit: Use a sharp, high-speed steel bit for metal. It cuts cleaner.

- Set the Speed: Go slow for metal to avoid overheating. Check your drill press manual for the best settings.

One trick I swear by is using a center punch. Tap it with a hammer to mark your spot. It keeps the bit from slipping, especially on slick metal surfaces.

Techniques for Better Precision

Once your drill press is set, focus on how you drill. These methods have worked wonders for me:

- Start Small: Drill a pilot hole with a smaller bit first. It guides the larger bit and reduces strain.

- Apply Steady Pressure: Push down gently and evenly. Too much force can bend the bit or ruin the hole.

- Use Cutting Oil: A few drops on the bit cools it down and makes drilling metal smoother.

- Clear the Chips: Stop now and then to brush away metal shavings. It keeps your hole clean and accurate.

I remember drilling a thick steel sheet without oil once. The bit got so hot it dulled in minutes. Now, I never skip that step—it’s a small effort for big results.

Common Mistakes to Avoid

Even pros mess up sometimes. Here are pitfalls I’ve seen—and made—plus how to dodge them:

| Mistake | Fix It |

|---|---|

| Loose Workpiece | Double-check clamps or vise |

| Wrong Speed | Match speed to material and bit |

| Dull Bit | Sharpen or replace it |

| Too Much Pressure | Let the bit do the work |

One time, I pushed too hard and snapped a bit mid-project. Now, I ease up and let the drill press handle the heavy lifting. Patience pays off.

Advanced Tips for Pros

Ready to level up? These tricks take your precision to new heights:

- Use a Vise: A drill press vise holds odd-shaped pieces steady, even for angled cuts.

- Set a Depth Stop: This keeps every hole the same depth—perfect for repetitive tasks.

- Add a Laser Guide: Some models have lasers to line up your bit exactly where you want it.

I added a vise to my setup last year, and it’s been a lifesaver for tricky angles. If you work with metal often, it’s worth the investment.

Keeping Your Drill Press in Top Shape

A well-maintained drill press lasts longer and performs better. Here’s my routine:

- Clean It Up: Brush off dust and shavings after every use. Power tools thrive on care.

- Lubricate Parts: Add oil to moving parts like the quill and spindle monthly.

- Check the Belt: Look for cracks or wear and replace it if needed.

- Sharpen Bits: A dull bit ruins precision—keep them sharp or swap them out.

Keeping your workspace tidy helps too. While power washers blast away big messes, they’re overkill here. I use a brush and compressed air instead. It’s quick and keeps my drill press spotless.

Safety First

Power tools demand respect. Follow these rules to stay safe:

- Wear safety glasses to shield your eyes.

- Keep hands clear of the spinning bit.

- Unplug the machine before swapping bits.

- Tie back long hair and avoid loose clothing.

I’ve seen folks skip glasses and regret it when chips fly. It’s a simple habit that saves trouble.

Wrapping Up

Mastering the drill press takes practice, but these techniques make it easier. Set up carefully, drill smart, and maintain your tool well. Soon, you’ll handle power tools for metalworking like a pro. Keep at it—your next project will thank you!

Related Mastering the Drill Press: Techniques for Better Precision:

- How to Prep Your Room for a Perfect Paint Job

- Essential Construction Tools for Masonry Work: A Comprehensive Guide

- How to Choose the Right Power Drill for Your Projects

- Tool Care Basics: Essential Tips to Keep Your Gear Like New

- Top 10 Must-Have Tools for Every Workshop

- A Beginner's Guide to Workman Tools: Essentials, Toolboxes, and Safety Tips

- Essential Safety Checks for Power Tools

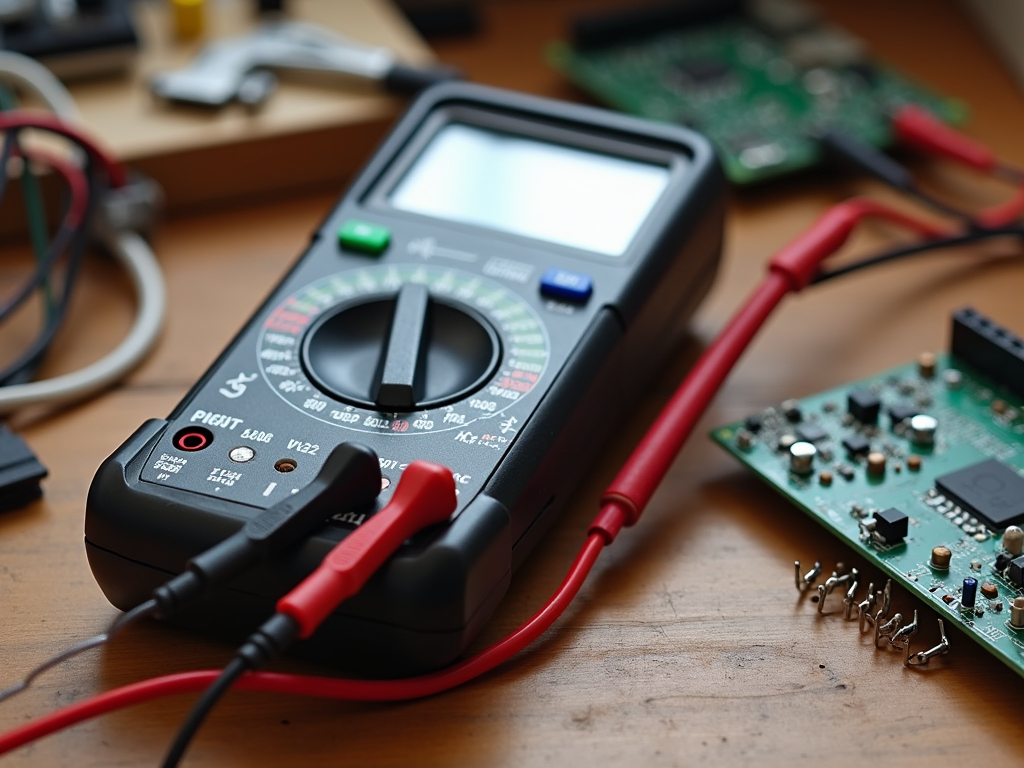

- How to Use a Multimeter for Beginners: A Step-by-Step Guide

- The Ultimate Guide to Mobile Storage Carts for Tools

- Ergonomic Power Drills for Reduced Fatigue: A Comprehensive Guide

- How to Set Up Your Workshop: A Comprehensive Guide

- Safety First: Essential Gear for Every DIY Enthusiast